- Home

-

Pruducts & Applicaition

Pruducts

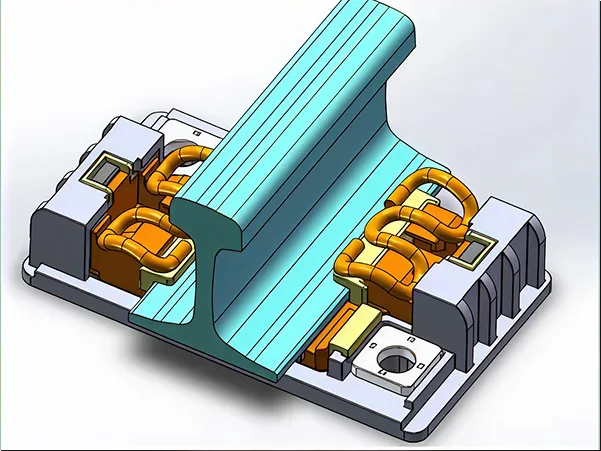

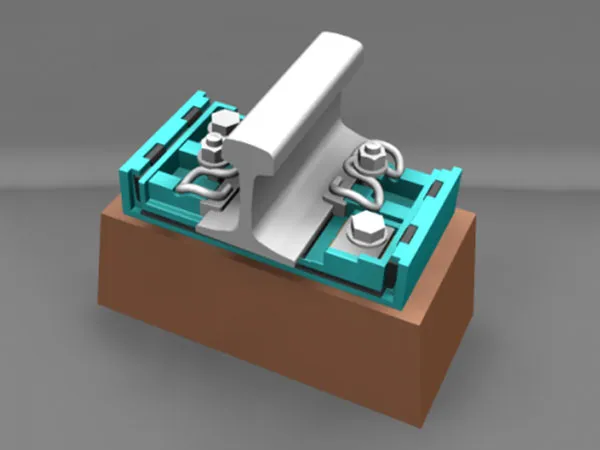

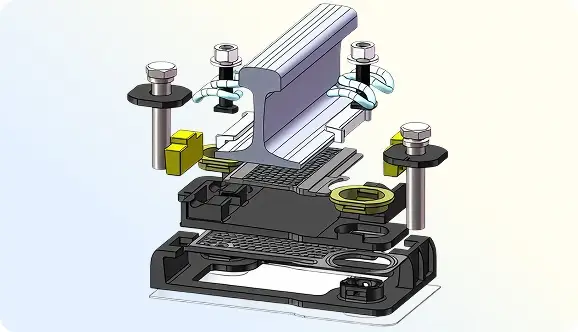

Vibration Reduction Fastener

Dedicated Fastening System

Various Parts and Components

Composite Protective Cover

Composite Evacuation Platform

Synthetic Sleeper

Rubber-Plastic Composite Rail Sleeper

Rail Damping Tuned Mass Damper for Vibration and Noise Reduction

Polyurethane Ballast Bed Isolation Mat

Polyurethane Under Sleeper Pad (USP)

Fastening Systems

- About Us

- News

- Contact