Rubber-Plastic Composite Rail Sleeper Overview

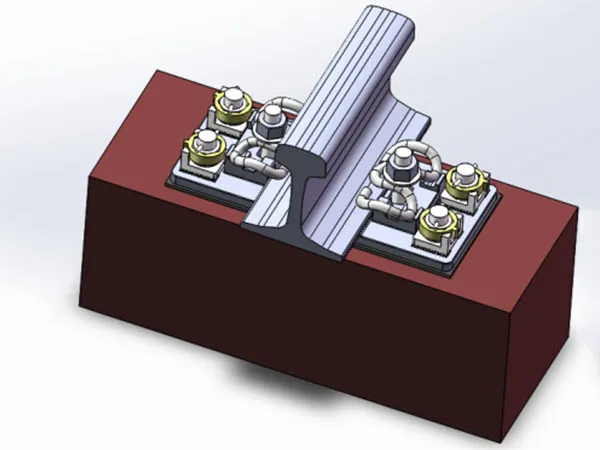

The rubber-plastic composite rail sleeper is made from recyclable materials, with the main material being a non-metallic material. The product meets the requirements of ISO12856-1 B Type. Compared to concrete rail sleepers, it has the advantages of good elasticity, light weight, strong manufacturability, repairability, good cold resistance, wind resistance, and good insulation properties. Compared to wooden sleepers, it has the advantages such as corrosion resistance, resistance to acids and bases, resistance to insect damage, and recyclability, which are particularly highlighted in today's situation where tree resources are scarce.

The rubber-plastic composite rail sleeper has the characteristics of high bending strength, low water absorption rate, noise and vibration reduction, and low maintenance cost. It can be applied in various working conditions such as ballast track bed, integral track bed, tunnel, bridge, and turnout, and meets the requirements of different transportation routes.

Characteristics

Environmental protection

Through the innovation of material technology, it is made using recycled rubber and plastic materials, which is both economical and environmentally friendly, and can be reused. It is a 100% recyclable sustainable product.

Insulating and water-resistant

Excellent insulation properties, with extremely low water absorption in the material, to prevent stray currents and water damage.

Lightweight and versatile

Low density and good elasticity make it suitable for various railway conditions, and it is easy to install on-site.

Dimensions can be customized

Production adopts a continuous extrusion method, and the length of the product can be adjusted according to customer requirements.

Easy to process and repairable

It can be processed in the same way as wood; it can have grooves, holes, and height adjustments on the side and top surfaces. After construction errors or damage, it can be quickly repaired on-site. The surface can be treated for slip resistance.

Service life

It has a longer lifespan compared to wooden sleepers; it can prevent freezing and cracking in extremely cold climates and has good weather resistance. The overall maintenance cost is low.

Applications

Mainline & branch railways

Urban metro and tram lines

Railway bridges and tunnels

Turnouts and switches

Track renewal projects

Coastal and high-humidity environments

Technical Specifications

Material Properties

|

Unit

|

ISO12856-1 B Type Technical Requirements

|

Results

|

Bending Strength

|

MPa

|

≥18

|

51.1

|

Flexural Modulus

|

MPa

|

≥2500

|

25.17

|

Longitudinal Com-pression Strength

|

N/mm²

|

≥8

|

49.4

|

Lateral Compression Strength

|

N/mm²

|

≥8

|

15

|

Shear Strength

|

N/mm²

|

≥4.5

|

14.5

|

Alternating-Current Breakdown Voltage

|

kV

|

≥20

|

30

|

Direct-Current Insulation Resistance

|

Ω

|

≥2×104

|

6×108

|

Water Absorption

|

%

|

≤2

|

0.005

|

Mass Density

|

g/cm³

|

≥0.8

|

1.08

|

Linear Expansion Coefficient

|

K-1

|

≤6✖10-5

|

5✖10-5

|

Tensile Strength of Threaded Spike

|

kN

|

/

|

60

|

Why Choose Our Rubber-Plastic Composite Sleepers?

Long-term cost efficiency with minimal maintenance

Sustainable and environmentally responsible

Excellent vibration damping and track stability

Compatible with existing fastening systems

Lightweight and easy to handle

Ready to Upgrade Your Tracks?

Invest in rubber-plastic composite rail sleepers for a safe, durable, and eco-friendly railway solution. Contact us today to request a quote or learn more about our customizable options for your project.