Polyurethane Ballast Bed Isolation Mat Details

The polyurethane vibration mat is a low-density polyurethane microporous elastomer, mainly used under urban rail transit track beds or in scenarios such as vibration reduction isolation trenches and isolation foundations. It relies on its good elasticity to reduce vibration excitation transmitted to surrounding buildings, serving the function of vibration and noise reduction.

The polyurethane microporous elastomer vibration mat uses area support and relies on its internal microporous structure for elasticity, rather than structural deformation, resulting in better vibration reduction.

Compared to rubber track bed mats, it has advantages such as lower density, more production-friendly environment, higher degree of automation, higher production efficiency, and easier installation.

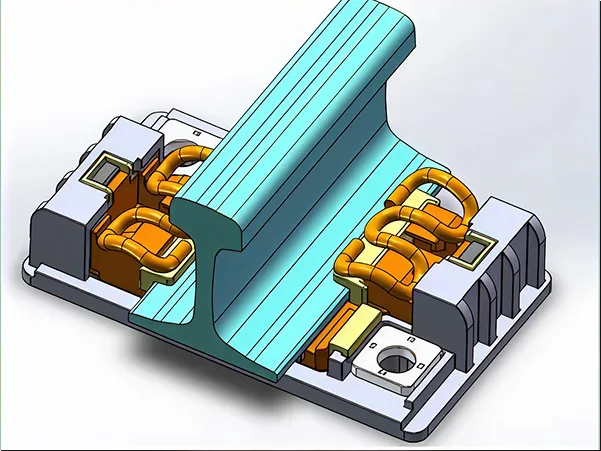

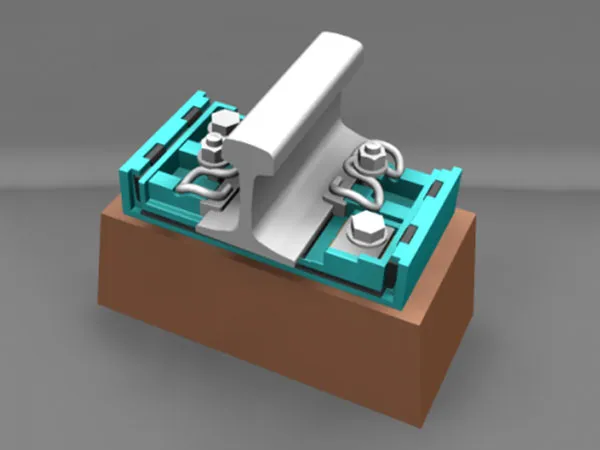

Structure and Composition

These mats are typically engineered as a "sandwich" of high-performance materials designed to survive harsh railway environments for decades.

The Resilient Layer (Core): Made of microcellular polyurethane (often polyether-urethane). Unlike rubber, PU is volume-compressible, meaning it can absorb energy and deflect without requiring hollow cavities or specific profiles.

The Protective Layer (Top): A high-strength geotextile or fleece covers the PU. This layer protects the mat from being punctured by the sharp edges of the ballast stones and helps distribute the heavy load of the train.

The bottom Layer (Optional): Some mats include a slip-resistant coating or a secondary drainage layer to prevent water buildup between the mat and the concrete or soil substrate.

Polyurethane Ballast Bed Isolation Mat Advantages

The polyurethane ballast bed isolation Mat is installed between the ballast and sleepers, the mat acts as a flexible buffer that absorbs dynamic loads from passing trains. This not only minimizes vibration transmission to the subgrade but also effectively reduces track-induced noise, improving comfort for passengers and nearby communities.

Key advantages of polyurethane ballast mats include:

High Vibration Damping: Efficiently absorbs and dissipates dynamic forces from train operations.

Enhanced Track Stability: Maintains ballast alignment under repeated loading, reducing maintenance costs.

Durable Material Performance: Resistant to temperature extremes, UV exposure, and chemical corrosion.

Noise Reduction: Significantly lowers track-borne noise levels, contributing to a quieter railway environment.

Polyurethane ballast mats are widely adopted in high-speed rail, urban transit systems, and heavy-haul freight lines where vibration control, noise reduction, and track longevity are critical. Their integration into modern railway infrastructure represents a cost-effective solution for safer, quieter, and more sustainable rail operations.

Main Performance Parameters

|

Item

|

Unit

|

|

Tensile Strength

|

MPa

|

|

Elongation at Break

|

%

|

|

Constant Compression Permanent Deformation(70℃×24h,Compression30% )

|

%

|

|

Aging Performance (70℃, 168h)(70℃,168h)

|

Tensile Strength Change Rate

|

%

|

|

Elongation at Break Change Rate

|

%

|

|

Liquid Resistance

(50℃,168h,Distilled Water)

|

Tensile Strength Change Rate

|

%

|

|

Elongation at Break Change Rate

|

%

|

|

Static Stiffness

|

N/mm³

|

|

Dynamic-static Stiffness Ratio

|

None

|

|

Fatigue Performance After

10 Million Cycles

|

Static Stiffness Change Rate

|

%

|

|

Thickness Change Rate

|

%

|

|

No Surface Damage or Delamination

|

-

|