Special Vehicle Technology Solutions: Lightweighting, Vibration Control, and Application of Special Polymer Materials

In today’s era of extreme operational demands, high mobility, and stealth requirements, special vehicles—including armored defense units, polar exploration platforms, and emergency response systems—are undergoing a transformation from traditional manufacturing to extreme performance engineering. To meet these complex challenges, our integrated solutions leverage lightweight composite materials, vibration and noise control (NVH), and high-performance polymers to enhance mobility, durability, and operational efficiency.

Lightweight Composites: Balancing Mobility and Protection

Special vehicles face a natural conflict between increasing armor protection and maintaining high mobility. Traditional steel and aluminum structures are reaching physical limits, but advanced lightweight composite solutions offer a breakthrough.

Carbon Fiber/Resin-Based Components: Using integrated molding technology to replace traditional welded metal structures, these components achieve over 30% weight reduction, significantly improving power-to-weight ratios and range.

Impact-Resistant Sandwich Structures: Combining high-performance fibers with honeycomb or foam cores, these structures provide superior ballistic protection while absorbing energy to safeguard the crew cabin.

Corrosion-Resistant and All-Weather Performance: Designed for high humidity, salt spray, and extreme climates, these materials extend the service life of vehicles in harsh environments.

These innovations allow vehicles to maintain or even enhance protection levels while reducing weight and improving fuel efficiency.

Vibration and Noise Control: Optimizing NVH Performance

Excessive vibration and noise not only fatigue operators but also compromise the stability of onboard electronic systems. Our NVH solutions include:

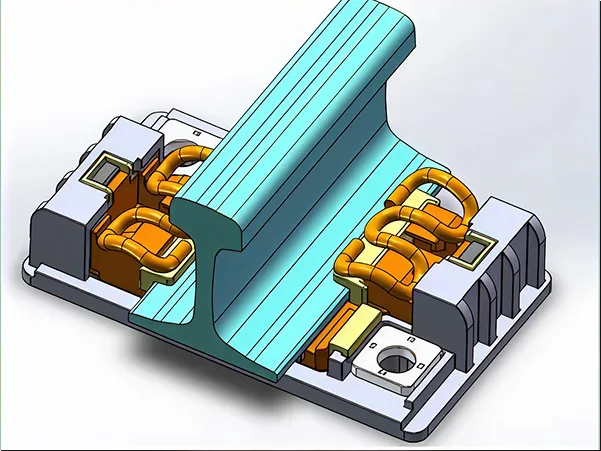

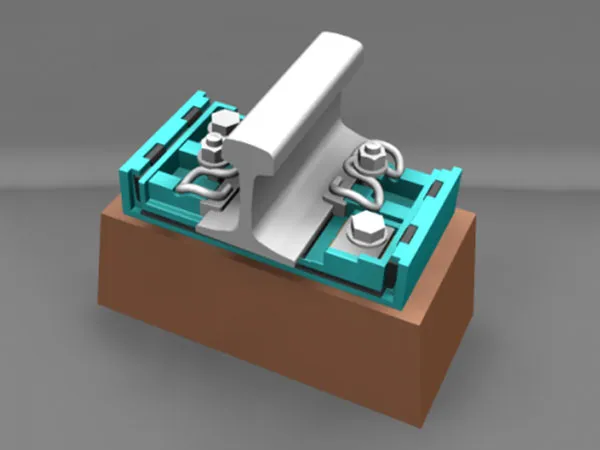

Active and Passive Damping Systems: Utilizing damping alloys and specialized rubber composite bushings to isolate low-frequency vibrations transmitted from the drivetrain to the vehicle body.

Track and Wheeled Noise Reduction Solutions: High-strength, wear-resistant composite pads reduce structural noise generated by track-ground interactions, enhancing acoustic stealth.

Precision Instrument Vibration Platforms: Customized frequency response optimization ensures the accuracy of on-board radar, optical targeting, and other sensitive equipment under dynamic conditions.

These systems enhance crew comfort, prolong component life, and improve overall operational efficiency.

High-Performance Polymers: Reliable Protection in Extreme Conditions

From seals to electrical insulation, high-performance polymers act as the hidden guardians of special vehicle functionality.

Extreme Temperature Elastomers: Maintain elasticity from -60°C to 200°C, ensuring powertrain sealing in polar or desert environments.

Electromagnetic Shielding and Absorbing Materials: Polymer-based composites provide excellent electromagnetic compatibility, mitigating electronic warfare threats.

Flame-Retardant and Low-Smoke Materials: Interior components and cabling meet the highest safety standards, buying critical evacuation time in fire scenarios.

These materials increase vehicle reliability, reduce maintenance, and ensure safe operation under extreme conditions.

Application Areas

Our solutions are already deployed in key special vehicle domains:

Field Command and Control Platforms: Lightweight structures with robust electromagnetic protection.

Tracked Armored Transport Vehicles: Reduced operational noise and extended drivetrain life.

Unmanned Ground Systems (UGS): High-strength frameworks with extreme environment resistance.

Polar and Specialized Operational Vehicles: Ensured structural integrity and sealing in extreme low temperatures.

Why Choose Our Solutions?

Customized R&D: From material design and simulation to prototype testing, we provide full-cycle, tailor-made solutions for each vehicle.

Interdisciplinary Integration: Materials science, mechanical simulation, and acoustic control are combined into a single, comprehensive solution.

Reliability Verification: All products undergo rigorous laboratory and field testing to perform flawlessly in critical missions.

Conclusion

By combining lightweight composite structures, vibration and noise control, and high-performance polymers, our solutions empower special vehicles to achieve unprecedented mobility, safety, and reliability. Whether in extreme environments or high-demand operational scenarios, these technologies deliver a true performance revolution, making every special vehicle more efficient, durable, and mission-ready.