Integrated Solutions for Innovative Materials and Technologies in Rail Transit

In the modern rail transit industry, lightweighting, comfort, safety, and sustainable operation have become core challenges. We provide rail transit companies with efficient, reliable, and low-cost integrated solutions through innovative technologies such as composite material lightweighting, track vibration and noise control, and specialty polymer materials, helping to achieve performance optimization, energy conservation, and environmental friendliness.

Composite Material Lightweighting: Creating "Lighter, More Efficient" Trains

Lightweighting is a key strategy for improving train energy efficiency, reducing operating costs, and extending component lifespan. Traditional metal materials suffer from problems such as heavy weight, susceptibility to corrosion, and high design limitations, while high-performance composite materials offer a solution.

Solution: High-Performance Fiber Reinforced Polymer (FRP) Composites

Utilizing carbon fiber, glass fiber, and advanced resin systems, we develop high-strength, low-density composite structural components to achieve overall train lightweighting while ensuring safety and durability.

Main Application Scenarios: Car Body Structural Components: Front fairing, side walls, floor, driver's cab frame, etc., with overall weight reduction reaching over 15%.

Interior Systems: Seat frames, luggage racks, air ducts, etc., featuring high flame retardancy (meeting rail transit fire safety standards) and design freedom.

Bogie Non-Load-Bearing Components: Anti-roll torsion bars and auxiliary suspension supports, fully utilizing the excellent fatigue performance of composite materials.

Core Values:

Energy Saving and Emission Reduction: Reducing the overall weight of the train and decreasing traction energy consumption.

Load Optimization: Reducing impact on tracks and infrastructure, extending maintenance cycles.

Corrosion and Weather Resistance: Adapting to complex environments and extending vehicle lifespan.

Safety and Reliability: Materials with strong energy absorption capacity, improving passenger safety.

Track Vibration and Noise Control: Creating a "Quieter and More Comfortable" Riding Experience

During high-speed train operation, wheel-rail noise, aerodynamic noise, and structure-transmitted sound have a significant impact on passenger comfort and the urban environment.

Solution: High-Performance Damping and Sound Insulation System

Combining special polymer materials, we have developed a comprehensive system integrating **isolation** and **absorption & barrier** to effectively reduce vibration propagation and noise radiation.

Key Application Technologies:

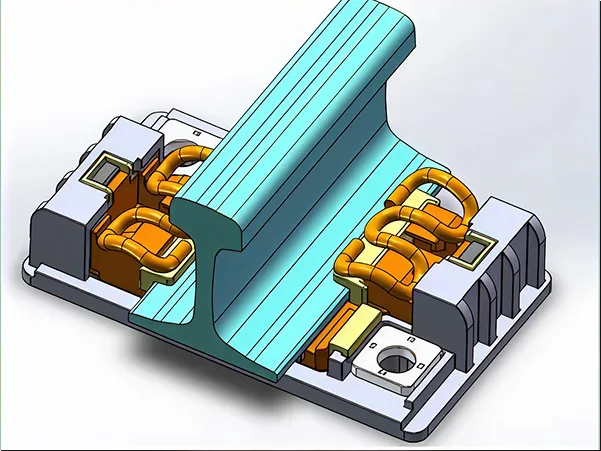

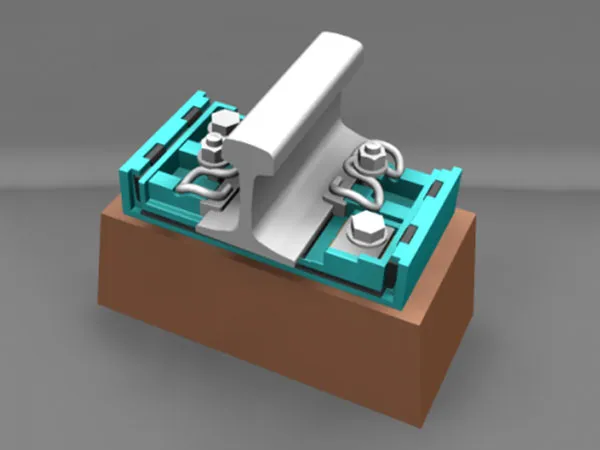

Floating Plates/Elastic Support Pads: Using polyurethane or rubber elastomers, these isolate low-frequency vibrations, reducing the noise impact of subways and light rail on buildings.

Rail Damping Materials: High-polymer viscoelastic damping blocks on both sides of the rails rapidly dissipate wheel-rail vibration energy, effectively reducing screeching noise.

Carriage Sound Insulation Packages: Multi-layered composite sound-absorbing felt and microporous sound-absorbing panels reduce interior noise by 5-8 decibels.

Core Values:

Enhanced Passenger Comfort: Significantly improves the interior noise environment.

Environmentally Friendly: Complies with urban environmental regulations, reducing noise pollution for residents along the route.

Vehicle and Track Protection: Reduces the impact of vibration on structural fatigue, extending service life.

Specialty Polymer Materials: Ensuring Safer and More Durable Operation

Rail transit demands extremely high material performance, especially in fire resistance, wear resistance, and weather resistance, which traditional plastics or rubber cannot meet.

Solution: Customized Functional Polymers

Developing materials suitable for the "three high requirements" (high standards, high performance, and high safety) of rail transit to improve system reliability and maintenance efficiency.

Key Application Technologies:

High Flame Retardant/Low Smoke Toxicity (FST) Materials: Utilizing specialty engineering plastics such as PEI, PES, and PEEK, used for interior panels, cable sheaths, and connectors, meeting the highest fire resistance standard of EN 45545-2.

High-Performance Seals/Damping Components: Fluororubber, silicone rubber, and polyurethane materials, applied to door seals, windshields, air springs, etc., ensuring lasting elasticity under extreme temperatures and chemical environments.

Wear-Resistant Guide Rails and Bearings: UHMWPE and specialty engineering plastic sliding parts, low friction, maintenance-free.

Core Values:

Passenger Safety: FST's high-standard materials ensure life safety in the event of a fire.

Extended Service Life: Wear-resistant and weather-resistant, reducing the frequency of parts replacement.

Simplified Operation and Maintenance: Reduced failure rate and optimized maintenance costs.

Comprehensive Advantages

Through the synergistic application of lightweight composite materials, vibration and noise control, and special polymer materials, we provide rail transit companies with:

High Efficiency and Energy Saving: Lightweight design reduces energy consumption.

Comfort and Safety: Noise and vibration reduction, fire protection.

Low Maintenance Costs: Wear-resistant and weather-resistant, extending service life.

Green and Environmentally Friendly: Reduced noise pollution, supporting sustainable development.

Choosing our innovative materials and technology solutions means choosing the future driving force for high-performance, green, and intelligent development in the rail transit industry.