-

High-Grade Vibration Reduction Fastener

-

High-Grade Vibration Reduction Fastener

High-Grade Vibration Reduction Fastener Introduction

In modern machinery, transportation, and construction industries, vibration can lead to equipment wear, noise, and structural damage. To combat these challenges, high-grade vibration reduction fasteners have emerged as a critical solution, ensuring both operational stability and longevity of equipment.

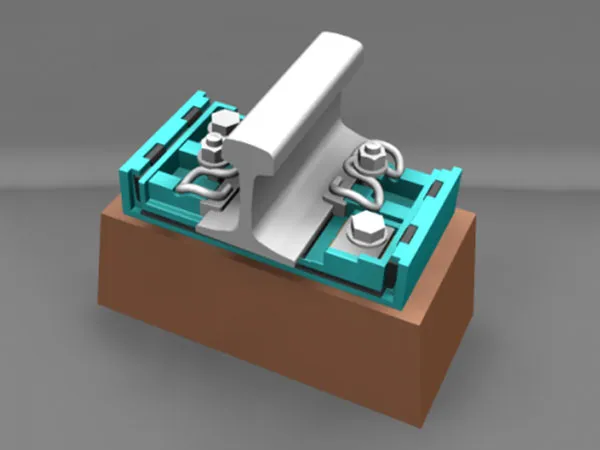

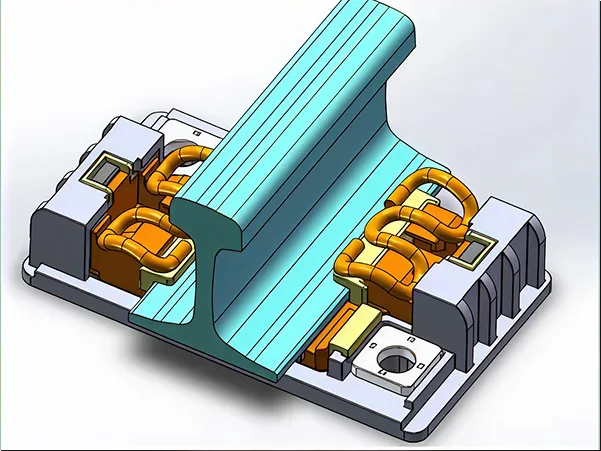

The high-grade vibration reduction fastener uses an elastic rail clip to fasten the rail, while the fastener has low vertical stiffness, with a design value of vertical stiffness reaching 6-10kN/mm, and a vibration reduction effect of more than 10dB.

By adjusting the structure and arrangement of the elastic pad, the fastener minimizes the vertical stiffness while ensuring stability to provide higher vibration reduction, achieving the best vibration reduction effect while maintaining a unified rail fastening method.

It can be applied to underground lines or elevated lines of urban rail transit (including municipal railways) including lines with R350 curve radius, having wide working condition applicability.

Main Performance Parameters

|

Item

|

Techincal Indicators

|

|

Static Stiffness and Dynamic-to-Static Ratio

(Load:5~35kN)

|

6~10kN/mm;

The dynamic-to-static ratio:<1.4;

|

|

Fastening Interface

|

Compatible with various rails, sleepers, and tie hole spacings.

Installation height and rail cant can be custom-designed according to requirements.

|

|

Orbital Adjustment Amount

|

Gauge adjustment amount:-20~+20mm;

Orbital height adjustment amount:0~30mm;

|

|

Performance After Fatigue

|

After being subjected to 3 million cycles of fatigue testing under

vertical loads of 8.6–43 kN and lateral loads of 6.8–34 kN, the

change rate in static stiffness does not exceed 10%, the gauge

change does not exceed 6 mm, and no damage occurs to any

components. The dynamic displacement of the rail was measured,

showing that the unilateral rail head dynamic displacement does not exceed 3 mm,

and the unilateral rail base does not exceed 2.5 mm.

|

Benefits of Using High-Grade Vibration Reduction Fasteners

Reduced Noise and Resonance: Creates quieter, more comfortable operating environments.

Prolonged Equipment Life: Minimizes fatigue and wear on components caused by vibration.

Enhanced Safety: Reduces the risk of structural damage or fastener loosening under dynamic loads.

Energy Efficiency: By stabilizing machinery operation, it can improve overall energy efficiency and performance.

Common Applications

High-grade vibration reduction fasteners are widely used in industries where vibration control is critical:

Railway Systems: Fastening tracks and sleepers while minimizing noise and vibration.

Automotive & Heavy Vehicles: Engine mounts, suspension systems, and chassis components.

Industrial Machinery: Compressors, turbines, and production lines.

Construction Equipment: Cranes, excavators, and other vibrating machinery.

Installation Considerations

To maximize performance, these fasteners must be installed according to precise torque and alignment specifications. Improper installation can compromise vibration absorption and lead to premature wear. Specialized installation guides and maintenance tips are recommended for optimal performance.

High-grade vibration reduction fasteners are essential components for modern machinery and infrastructure where vibration, noise, and wear must be controlled. Investing in high-quality fasteners ensures safer, quieter, and more reliable operation, making them an indispensable part of industrial, automotive, and railway systems.