-

Dedicated Vibration-Damping Fastening System for Railway Turnouts

-

Dedicated Vibration-Damping Fastening System for Railway Turnouts

Dedicated Vibration-Damping Fastening System for Railway Turnouts Introduction

The special vibration reduction fastener for turnout improves vibration reduction by more than 5dB compared to ordinary turnout fasteners, belonging to the medium-grade vibration reduction category.

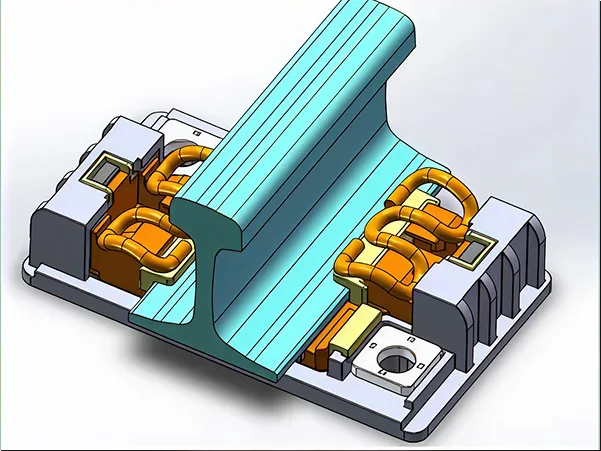

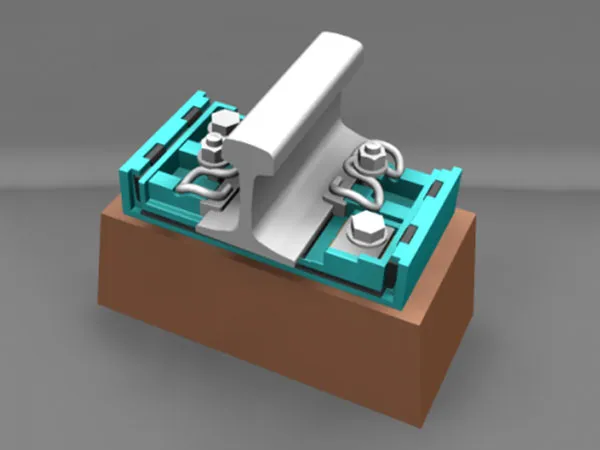

The main body uses a self-locking mechanism to assemble the upper iron baseplate, middle rubber pad, and lower iron baseplate together. It relies on the elasticity of the middle rubber pad layer to achieve good vibration reduction effects, while enabling convenient replacement and maintenance of components.

The fastening system connects the fastener assembly and the coupling baseplate tightly to the track bed foundation through threaded rail spikes, greatly enhancing the system's pull-out resistance, effectively avoiding operational risks caused by insufficient pull-out resistance of vulcanized turnout vibration reducers.

Why Turnouts Require Dedicated Damping

Railway turnouts are the most complex and vulnerable parts of a track network. Standard fastening systems often fall short in these areas due to:

Impact Loading: The "gap" or "crossing" area (frog) causes vertical shocks as the wheel flange passes through.

Lateral Forces: Diverging movements create high lateral pressure that standard fasteners cannot absorb effectively.

Maintenance Intensity: Turnouts account for a disproportionate share of maintenance costs; vibration damping extends the life of expensive components like switch blades and frogs.

Core Components

A dedicated system typically uses a "multi-layer" or "split" structure to decouple the rail from the foundation.

|

Component

|

Function

|

|

High-Elasticity Rail Pad

|

Placed directly under the rail to provide initial shock absorption.

|

|

Baseplate (Iron/Steel)

|

Distributes the load over a larger area; often includes a 1:40 slope for rail inclination.

|

|

Damping Cushion/Mat

|

A thick, resilient layer (often microcellular polyurethane) placed under the baseplate to isolate the sleeper from vibration.

|

|

Elastic Clips (e.g., WJ-7 or SKL)

|

Provide high "toe load" (clamping force) to keep the rail stable while allowing controlled vertical movement.

|

|

Insulating Sleeves

|

Protect bolts from shear stress and provide electrical isolation for signaling.

|

Main Performance Parameters

|

Item

|

Technical Indicators

|

|

Static Stiffness and Dynamic-to-Static Ratio

(Load:5~35kN)

|

17~23kN/mm;

The dynamic-to-static ratio:<1.3;

|

|

Fastening Interface

|

Compatible with various rails, sleepers, and tie hole spacings. Installation height and rail cant can be custom-designed according to requirements.

|

|

Orbital Adjustment Amount

|

Gauge adjustment amount:Not lower than the matching ordinary turnout fasteners

Orbital height adjustment amount:0~30mm;

|

|

Performance After Fatigue

|

After being subjected to 3 million cycles of fatigue testing under vertical loads of 8.6–43 kN and lateral loads of 6.8–34 kN,

the change rate in static stiffness does not exceed 10%,

the gauge change does not exceed 6 mm, and no damage occurs to any components.

The dynamic displacement of the rail was measured, showing that the unilateral rail head dynamic displacement does not exceed 3 mm,

and the unilateral rail base does not exceed 2.5 mm.

|

Designed specifically for high-speed and heavy-load railway applications, this fastening system combines advanced materials with innovative damping technology to:

Minimize vibration transmission to the track structure and surrounding environment.

Enhance track stability under frequent train movements.

Prolong service life of turnout components and reduce maintenance frequency.

Ensure easy installation and maintenance with a robust, modular design.

Ideal for modern railways aiming to improve operational efficiency, passenger comfort, and infrastructure longevity, this vibration-damping fastening system is the perfect solution for upgrading or constructing high-performance turnouts.

Applications: High-speed rail, urban transit networks, heavy freight lines, and other railway infrastructure requiring advanced vibration control.