Fastening Systems of All Models: Comprehensive Vibration Damping Solutions

Kefei is committed to providing superior vibration damping fastener systems to customers worldwide. With a full range of production capabilities, we can meet diverse needs, from urban rail transit to heavy-duty railways, and from standard environments to extreme operating conditions.

1. Wide Range of Models

We understand that every railway project has unique requirements. That’s why our portfolio covers all fastening system models, including:

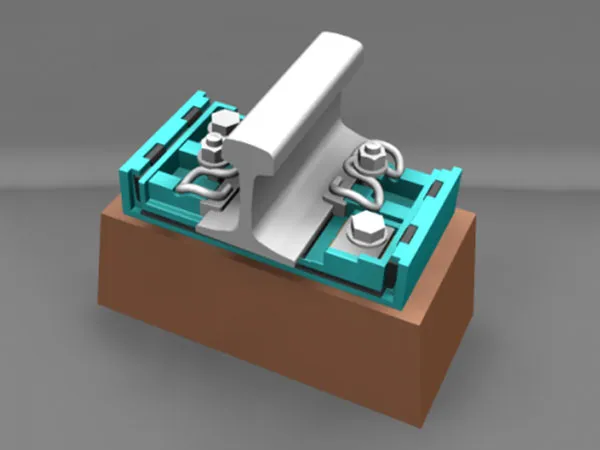

Single-layer and double-layer vibration reduction fasteners

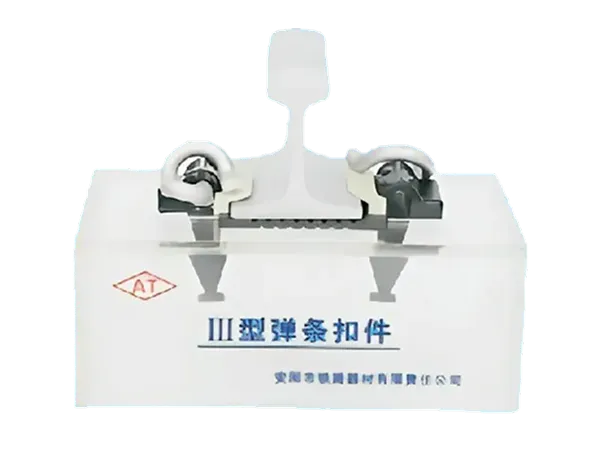

Shoulder-type and spring-type designs

Fasteners for concrete, wooden, and composite sleepers

Special high-speed rail fasteners

This comprehensive range ensures that no matter the project type—urban transit, high-speed rail, or freight lines—our systems deliver reliable performance.

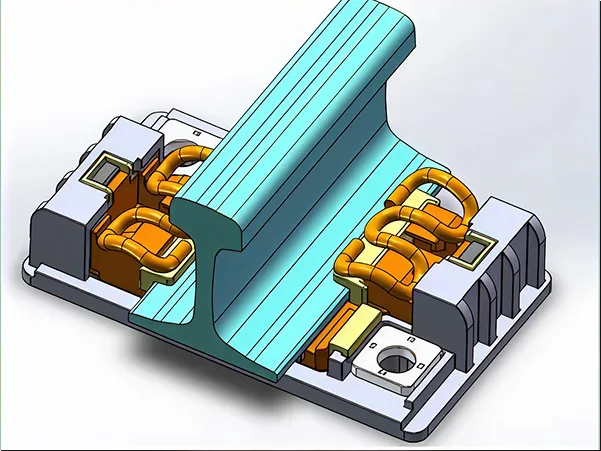

2. Advanced Vibration Reduction Technology

Our fastening systems are engineered to minimize rail vibrations and noise, improving passenger comfort and reducing wear on rolling stock and tracks. Key features include:

Non-linear damping components that absorb dynamic loads efficiently

Durable polyurethane or rubber elements for long-lasting elasticity

Corrosion-resistant materials suitable for harsh environments

By effectively controlling vibrations, our fasteners not only extend track service life but also reduce maintenance costs.

3. Customizable Solutions

Even though we offer a wide variety of standard models, we also provide tailored solutions to meet specific project demands. Whether it’s adjusting stiffness, load capacity, or material composition, our engineers collaborate closely with clients to ensure optimal performance.

4. Quality Assurance

Every fastening system undergoes strict quality control and testing to guarantee durability, reliability, and compliance with international railway standards. Our production facilities are equipped to manufacture all models at scale, ensuring consistent quality across batches.

5. Applications

Our vibration reduction fastening systems are widely used in:

High-speed railway lines

Urban metro and light rail networks

Freight and heavy-load tracks

Track upgrade and maintenance projects

6. Why Choose Us?

Comprehensive product range: All fastening system models available

Expertise in vibration reduction: Optimized design for noise and vibration control

Durable and reliable: Materials and craftsmanship ensure long service life

Customized support: Tailored solutions for unique track requirements

Whether your project requires standardized international models or non-standard fasteners designed for special slopes or curve radii, we can provide a "one-stop" production service. Full-model production is not just about quantity coverage, but also a commitment to quality.