-

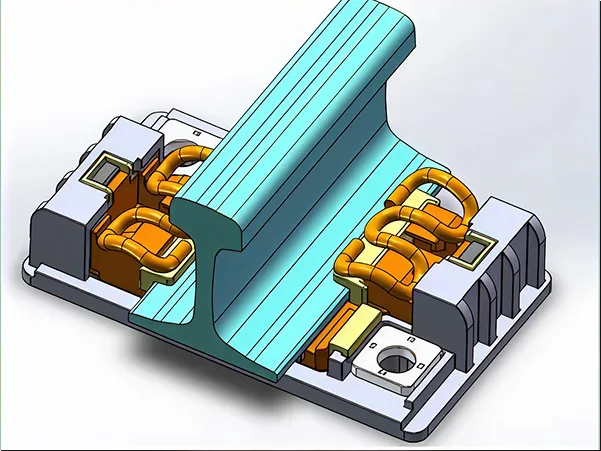

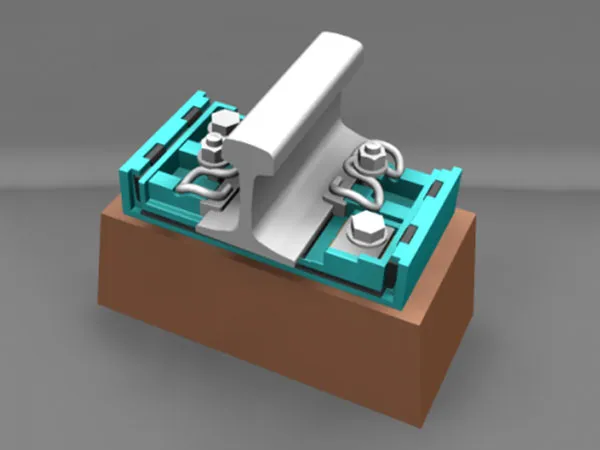

Shoulder Type Double-Layer Non-linear Vibration Reduction Fastener

-

Shoulder Type Double-Layer Non-linear Vibration Reduction Fastener

Shoulder Type Double-Layer Non-linear Vibration Reduction Fastener Introduction

The shoulder type double-layer non-linear vibration reduction fastener is a medium-grade vibration reduction fastener product. Compared with ordinary elastic separated fasteners, the actual online test vibration reduction effect reaches more than 5-8dB. Meanwhile, the fastener has the overall characteristics of high stability, high vibration reduction level, and easy maintenance.

It can be applied to underground lines or elevated lines of urban rail transit (including municipal railways) including lines with R350 curve radius, having wide working condition applicability.

Key Features

Double-Layer Elastic Structure

The fastener features two distinct layers of elastic material, each optimized for different load ranges. The upper layer handles light to medium loads, while the lower layer absorbs heavy dynamic forces, ensuring smooth load transition and minimal vibration.

Non-linear Vibration Reduction

Unlike traditional linear fasteners, the non-linear design adjusts stiffness according to the load. This means it offers softer cushioning under small loads and firmer support under heavier trains, effectively reducing micro-vibrations and extending track lifespan.

Shoulder-Type Configuration

The shoulder-shaped design improves lateral stability and evenly distributes forces across the rail and sleeper. This reduces the risk of rail displacement and wear, enhancing overall track safety.

Durable Materials

Made from high-performance polymers and steel alloys, the fastener is resistant to UV exposure, extreme temperatures, and fatigue. This ensures long-lasting performance even in challenging environments.

Maintenance-Friendly Design

Modular components allow for easy inspection, repair, and replacement without removing the entire track section, reducing downtime and maintenance costs.

Main performance parameters

|

Item

|

Technical Indicators

|

|

Static Stiffness and Dynamic-to-Static Ratio

(Load:5~35kN)

|

9~15kN/mm;

The dynamic-to-static ratio:<1.4;

|

|

Fastener Installation Height

|

40~50mm;

|

|

Orbital Adjustment Amount

|

Gauge adjustment amount:-28~+24mm;

Orbital height adjustment amount:0~40mm;

|

|

Performance After Fatigue

|

After being subjected to 3 million cycles of fatigue testing under vertical loads of 8.6–43 kN and lateral loads of 6.8–34 kN, the change rate in static stiffness does not exceed 10%, the gauge change does not exceed 6 mm, and no damage occurs to any components. The dynamic displacement of the rail was measured, showing that the unilateral rail head dynamic displacement does not exceed 3 mm, and the unilateral rail base does not exceed 2.5 mm.

|

Benefits

Noise and Vibration Reduction: Provides a quieter, smoother ride for passengers.

Extended Track Life: Reduces rail and fastener wear, lowering long-term maintenance costs.

Enhanced Safety and Comfort: Stabilizes rails and reduces vibrations transmitted to carriages.

Versatile Application: Suitable for high-speed trains, metros, heavy freight lines, and curved tracks.

Applications

High-Speed Rail Lines – Ensures smooth and stable operations for trains exceeding 250 km/h.

Urban Metro and Light Rail Systems – Minimizes vibration and noise in densely populated areas.

Freight Corridors – Supports heavy loads while reducing track fatigue.

Curved Tracks and High-Vibration Sections – Improves lateral stability in challenging track geometries.

Technical Considerations

Installation: Proper torque settings are crucial to maintain the non-linear elastic performance.

Inspection: Regular checks are recommended to monitor polymer layer wear and integrity.

Compatibility: Can be used with concrete, composite, or steel sleepers depending on track design.