High-Performance Materials and Vibration Reduction Solutions for Ships and Yachts

In modern ship and yacht design, finding a balance between high-speed navigation and cabin quietness is a core challenge for every shipbuilding company. Common pain points for ships in complex aquatic environments include:

Energy Efficiency Pressure: The heavy weight of traditional metal materials leads to high fuel consumption and limited range.

Structural Vibration: Mechanical vibrations generated by the power system are transmitted through the hull structure, affecting crew health and navigational safety.

Environmental Noise: High-end yacht customers have extremely high requirements for cabin quietness, necessitating effective isolation of engine and fluid noise.

Harsh Environments: High salt spray, high humidity, and strong ultraviolet radiation environments pose extreme challenges to material durability.

Our Technical Solutions

1. High-Performance Composite Materials: The Core of Lightweight Navigation

Advanced Resin-Based Composite Materials: Replacing traditional steel, achieving a hull weight reduction of 20%-40%, improving fuel efficiency and range.

Carbon Fiber/Glass Fiber Reinforced Sandwich Structures: Utilizing lightweight foam or honeycomb core materials, lowering the center of gravity while ensuring ultra-high rigidity, improving maneuverability and stability.

1. Integrated Molding Process: Reduces the use of fasteners, enhances hull integrity and airtightness, and extends service life.

Application Scenarios: Yacht hulls, deck structures, bulkheads, etc.

2. Rails and Propulsion Systems: Precise Vibration and Noise Control

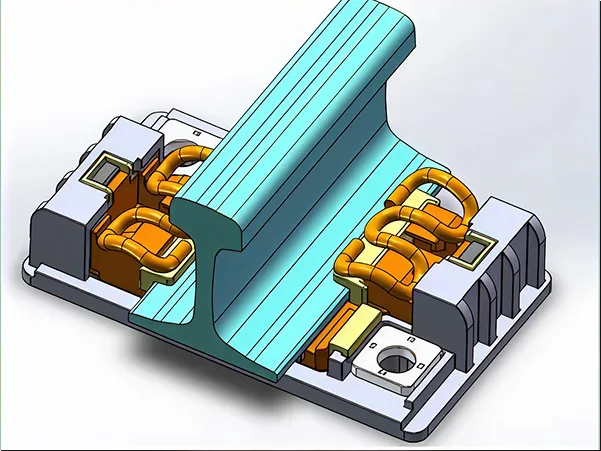

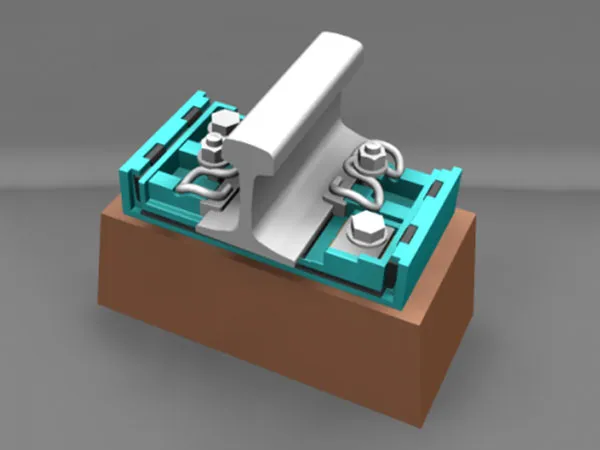

Vibration Isolation Bearings and Elastic Pads: Independently developed special damping elastomers effectively isolate structural noise generated by the main engine and generator sets.

Special Rail Dampers: For special-operation vessels with rail systems, high-performance constraint damping materials absorb impact kinetic energy and reduce vibration intensity.

Results: Reduces navigation noise by 10%-15 dB, significantly reduces vibration, and improves passenger comfort and equipment lifespan.

3. Special Polymer Materials: All-Round Protection in Extreme Environments

High-Performance Sealing and Insulation Materials: Aging-resistant, fire-retardant, ensuring cabin temperature control and structural safety.

Abrasion-Resistant and Anti-Bioadhesion Coatings: Reduces microbial adhesion to the hull bottom, reduces drag, and protects the hull from seawater corrosion.

Low-friction engineering plastics: Used in steering gears, slide rails, and mechanical transmission components to reduce wear and maintenance costs.

Applications: Underwater structures, deck cladding, mechanical transmission systems.

Why Choose Us?

|

Dimension

|

Direct benefits

|

|

Energy efficiency improvement

|

Weight reduction in the hull directly translates into longer range or higher speed.

|

|

Ultimate comfort

|

By reducing cabin noise by 10-15 dB through acoustic design, a five-star flight experience is created.

|

|

Maintenance costs

|

The excellent corrosion resistance of polymer materials significantly extends the maintenance cycle and reduces the total life cycle cost.

|

|

Green and environmentally friendly

|

To meet the increasingly stringent emission and environmental regulations of the International Maritime Organization (IMO).

|

Typical Application Scenarios

Luxury Private Yachts: Prioritizing ultimate stability and cabin quietness, while also considering composite material aesthetics and vibration reduction.

High-Speed Passenger Ferries: Focusing on lightweight design and operational economics.

Scientific Research and Special Operation Vessels: Prioritizing the protection of precision equipment and enhancing material durability.

Talk to Our Experts

We provide full-process technical support, from material selection and structural simulation to on-site installation guidance, helping you optimize vessel performance and upgrade new shipbuilding projects.