Rail Damping Tuned Mass Damper for Vibration and Noise Reduction Details

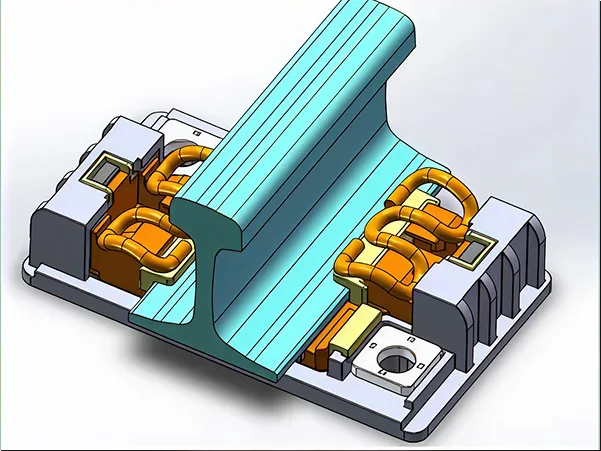

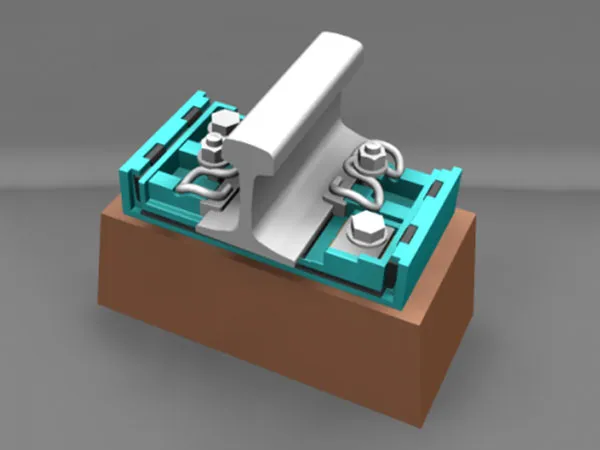

The rail damping tuned vibration and noise reducer is a rail damping system fixed on both sides of the rail web. It can effectively attenuate rail vibration, reduce noise radiation caused by wheel-rail impact, and also slow down wheel-rail wear, reducing maintenance workload.

The rail damping tuned vibration and noise reducer can effectively reduce track noise radiation by no less than 4dB, reduce rail vibration by no less than 3dB, significantly increase track vibration decay rate, and effectively control the generation and development of rail corrugation.

The system has the characteristics of few components, simple installation, high compatibility and designability with various track fasteners and other vibration reduction measures, and suitability for various track conditions. It can be applied to various lines such as underground lines, elevated lines, bridges, solid track beds, and ballasted tracks.

It can meet various needs for new line construction and existing line renovation.

How It Works: The Mass-Spring Principle

A rail TMD operates on the same physical principles as large-scale dampers in skyscrapers, but scaled down and tuned for high frequencies.

The Components: It consists of one or more heavy steel "oscillators" (masses) embedded in or separated by a resilient elastomeric (rubber) layer.

The Tuning: The stiffness of the rubber and the weight of the steel are precisely calculated so that the damper’s natural frequency matches the dominant vibration frequencies of the rail (typically 300 Hz to 2500 Hz for noise).

Energy Dissipation: When a train passes, the rail vibrates. The damper's internal mass oscillates in the opposite phase, transferring the vibration energy from the rail into the rubber layer, where it is converted into heat via hysteresis.

Key Benefits

Rail dampers are increasingly used in urban transit and high-speed rail for several reasons:

Precision Vibration Control: Tuned to counteract dominant vibration frequencies along rail tracks.

Noise Reduction: Helps significantly lower operational noise levels, enhancing the environmental performance of railway corridors.

Durable Design: Engineered to withstand extreme loads, temperature variations, and long-term rail operations.

Easy Installation & Maintenance: Compatible with existing rail systems and requires minimal upkeep.

Types of Rail Dampers

Discrete Rail Dampers: Small units clamped at intervals between sleepers (every 0.5 to 0.6 meters). These are the most common for retrofitting existing tracks.

Continuous Rail Dampers: Long strips applied along the entire length of the rail web. These provide very high damping but can be more difficult to install and maintain.

Multi-Degree-of-Freedom (MDOF) TMDs: These use multiple oscillators of different weights within a single unit to target a broader frequency range, covering both vertical and lateral rail movements.

Rail damping Tuned Mass Dampers represent a cutting-edge solution for modern railway networks seeking efficient vibration and noise mitigation. By integrating TMDs into rail infrastructure, operators can achieve safer, quieter, and more sustainable railway operations.