Railway infrastructure is evolving rapidly, with modern rail networks demanding materials that can withstand increasing loads, reduce maintenance costs, and minimize environmental impact. Among the key components of railway tracks are sleepers (also known as railroad ties), which provide support for rails and ensure track stability. Traditionally, concrete sleepers have been the industry standard, but synthetic railway sleepers are gaining popularity due to their numerous advantages. This article explores the differences between synthetic and concrete sleepers and evaluates which option is better for modern railways.

Synthetic Railway Sleepers vs Concrete Sleepers: Which Is Better for Modern Railways?

Understanding Railway Sleepers

Railway sleepers serve several critical functions:

Support rails and maintain the correct gauge.

Distribute loads from trains to the track ballast.

Absorb vibrations and reduce noise.

Provide durability under varying weather conditions.

Traditionally, sleepers were made of wood, steel, or concrete. Each material has its benefits and drawbacks, but with increasing environmental and operational demands, synthetic materials are becoming a viable alternative.

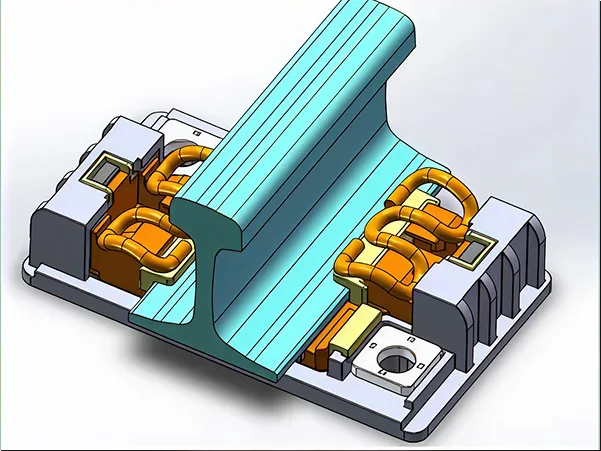

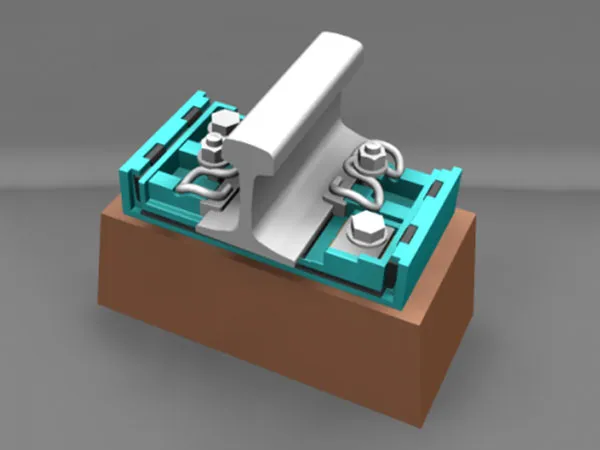

What Are Synthetic Railway Sleepers?

Synthetic railway sleepers are made from recycled plastics, polymers, and sometimes composite materials. They are designed to mimic or surpass the performance of traditional sleepers while offering additional benefits.

Key Features:

Durability: Resistant to rot, corrosion, and insect damage.

Lightweight: Easier and faster to install than concrete.

Eco-friendly: Often made from recycled materials, reducing environmental impact.

Maintenance: Lower lifecycle maintenance costs due to resistance to wear and environmental degradation.

Concrete Sleepers: Pros and Cons

Concrete sleepers are manufactured from reinforced concrete and have been widely used in modern rail networks for decades.

Advantages:

High load-bearing capacity: Ideal for heavy freight and high-speed trains.

Long lifespan: Typically last 40–50 years with minimal replacement.

Stability: Excellent dimensional stability, ensuring track alignment.

Disadvantages:

Weight: Very heavy, increasing installation and transportation costs.

Brittleness: Can crack under extreme impacts or ground movement.

Environmental impact: Manufacturing concrete produces significant CO₂ emissions.

Limited vibration absorption: Transfers more vibration to the ballast compared to synthetic sleepers.

Comparing Synthetic and Concrete Sleepers

Feature

|

Synthetic Sleepers

|

Concrete Sleepers

|

Weigh

|

Lightweight, easier to transport and install

|

Heavy, requires specialized equipment

|

Durability

|

Resistant to rot, corrosion, and chemicals

|

Very durable but brittle under impact

|

Environmental Impact

|

Often made from recycled materials

|

High carbon footprint during production

|

Maintenance

|

Low, minimal long-term costs

|

Low to moderate, but repairs can be costly

|

Vibration Absorption

|

High, reduces noise and track wear

|

Moderate, can transfer vibrations to ballast

|

Cost

|

Higher initial cost but lower lifecycle cost

|

Lower initial cost but higher installation cost

|

Applications and Suitability

High-speed railways: Both options are viable, but synthetic sleepers provide superior vibration control and noise reduction.

Urban and light rail networks: Synthetic sleepers are preferred for easy installation and reduced maintenance in confined areas.

Heavy freight lines: Concrete sleepers still dominate due to their load-bearing capacity.

Environmentally sensitive projects: Synthetic sleepers reduce carbon footprint and promote sustainability.

Conclusion: Which is Better?

There is no one-size-fits-all answer. Concrete sleepers excel in heavy-duty applications requiring maximum stability and long-term durability, while synthetic sleepers offer advantages in terms of environmental sustainability, ease of installation, vibration reduction, and lower long-term maintenance.

For modern railway projects that prioritize sustainability, speed of installation, and reduced lifecycle costs, synthetic railway sleepers are increasingly becoming the preferred choice. However, for extremely heavy freight lines or high-speed corridors where maximum load support is critical, concrete sleepers remain the benchmark.

Railway operators should evaluate their specific requirements, environmental goals, and long-term operational costs to determine the optimal sleeper material for each project.