Vibration reduction fasteners play a crucial role in modern machinery and structural applications. By minimizing vibrations, they help improve equipment longevity, reduce noise, and maintain structural integrity. However, proper installation is essential to unlock their full potential. In this guide, we’ll walk you through everything you need to know about installing vibration reduction fasteners effectively.

What Are Vibration Reduction Fasteners?

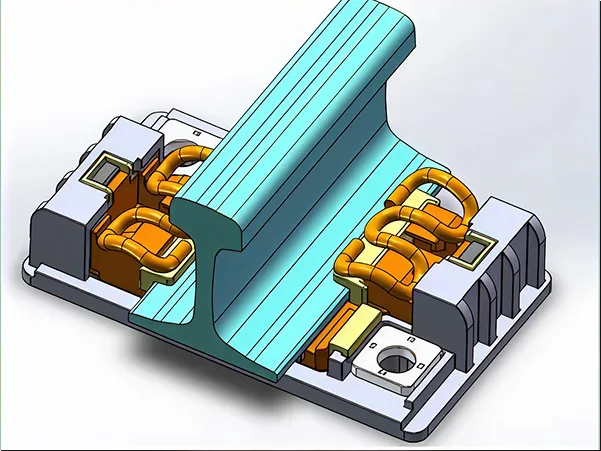

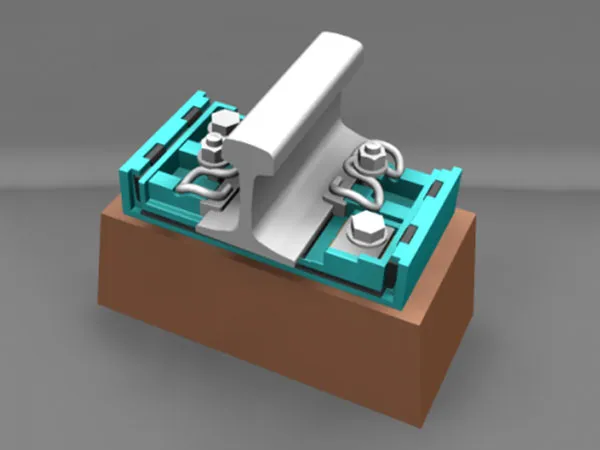

Vibration reduction fasteners are specialized bolts, screws, or anchors designed to absorb and dampen vibrations. Unlike standard fasteners, they incorporate materials like rubber, silicone, or spring elements to reduce the transmission of mechanical oscillations. These fasteners are commonly used in:

Industrial machinery and equipment

Automotive and transportation applications

HVAC systems

Precision instruments and electronics

By reducing vibration, they prevent loosening, enhance safety, and extend the lifespan of both fasteners and the structures they secure.

Installation Guide for Vibration Reduction Fasteners

Correct installation ensures that vibration reduction fasteners perform optimally. Follow these steps carefully:

1. Select the Right Fastener

Material compatibility: Ensure the fastener material matches the environment (e.g., stainless steel for corrosion resistance).

Load capacity: Choose fasteners rated for the expected mechanical load and vibration frequency.

Size and type: Confirm the diameter, length, and thread type suit your application.

2. Prepare the Surface

Clean the mounting surface thoroughly to remove dust, oil, or debris.

Inspect for surface irregularities or damage that could affect fastener performance.

3. Align Components Properly

Position the components accurately to prevent misalignment.

Misaligned parts can compromise the vibration damping effectiveness.

4. Apply Torque Correctly

Use a calibrated torque wrench to tighten the fasteners to the manufacturer’s recommended torque specification.

Over-tightening can damage the vibration-damping element, while under-tightening reduces effectiveness.

5. Use Additional Dampening Elements if Needed

Some installations may require washers, gaskets, or vibration pads to enhance damping performance.

Ensure these elements are compatible with the fastener and operating conditions.

6. Inspect and Test

After installation, inspect for proper seating and alignment.

Test the assembly under operational conditions to ensure vibrations are effectively reduced.

Periodic re-inspection is recommended for high-vibration environments.

Common Installation Mistakes to Avoid

Ignoring manufacturer guidelines: Using the wrong torque or installation method can damage fasteners.

Skipping surface preparation: Dirt or uneven surfaces reduce the effectiveness of vibration reduction.

Over-relying on fasteners alone: In some cases, additional vibration isolation measures may be required.

Benefits of Proper Installation

Extended equipment life: Minimizing vibrations reduces wear and tear.

Improved safety: Prevents loosening that can cause accidents or equipment failure.

Reduced maintenance costs: Well-installed fasteners require less frequent replacement.

Enhanced performance: Maintains structural stability and operational efficiency.

Conclusion

Installing vibration reduction fasteners correctly is more than just tightening bolts—it’s about ensuring your equipment performs safely, efficiently, and quietly. By following this step-by-step guide, you can maximize the benefits of vibration reduction technology, reduce maintenance costs, and enhance the longevity of your machinery.

For industries that depend on precision, stability, and durability, mastering vibration reduction fastener installation is an essential skill.