Fastening System for Synthetic Sleepers Introduction

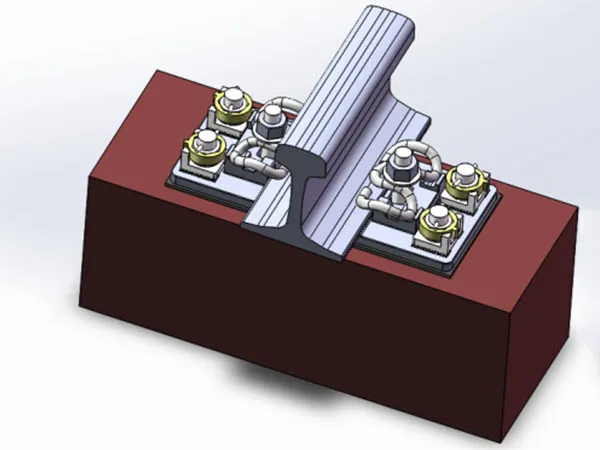

The RS series fastening system is a special fastener developed for polyurethane synthetic sleepers and plastic sleepers. Through systematic structural design, it achieves the characteristics of spike anti-loosening, gauge and level adjustment, easy installation, and reliable use. It can be widely used in various synthetic sleeper tracks, effectively solving problems such as fastener displacement and spike loosening caused by load fatigue and polymer material creep after long-term operation.

Components

A typical fastening system may include:

Rail Clips or Clamps – hold rails firmly in place while allowing slight elastic movement.

Insulating Pads – reduce vibration, electrical conductivity, and noise.

Base Plates – distribute load evenly to the sleeper and prevent wear.

Bolts and Fasteners – high-strength components resistant to corrosion and loosening.

Fastener Advantages and Characteristics

The anchoring system has a patented anti-loosening structure to prevent spike loosening caused by track system vibration during use.

Easy installation. No need to tap threaded holes in the synthetic sleeper during installation; simply connect the spike and the bottom anchor nut.

Convenient gauge and level adjustment. Gauge adjustment can be achieved by moving the fastening system relative to the long round spike hole, with an adjustment range of ±5mm per fastening point; Level adjustment of 0~30mm is achieved by placing leveling shims under the baseplate and under the rail.

Applications

Mainline and high-speed railways

Metro, light rail, and urban transit systems

Industrial and private railway tracks

Maintenance and replacement projects on composite sleeper tracks

Main Performance Parameters

|

NO.

|

Item Name

|

Performance Indicator

|

|

1

|

Static Stiffness

|

40~60kN/mm

|

|

2

|

Initial Installation Height

|

30±1mm;Or customized according to actual site requirements.

|

|

3

|

Rail Height Adjustment Capacity

|

0~+30mm

|

|

4

|

Rail Gauge Adjustment Capacity

|

±10mm

|

|

5

|

Insulation Resistance of Fastening System

|

≧5kΩ

|

Comparison of Fastening Methods

Composite sleepers are unique because they can support two distinct types of fastening philosophies:

|

Feature

|

Direct Fastening (Wood-like)

|

Indirect Fastening (Concrete-like)

|

|

Method

|

Screwed directly into the sleeper body.

|

Uses pre-embedded plastic dowels or anchors.

|

|

Advantage

|

High flexibility; can be installed anywhere.

|

Extremely high pull-out resistance for heavy haul.

|

|

Best Use

|

Switches, crossings, and bridge transoms.

|

Standard mainline tracks with high traffic.

|

|

Maintenance

|

Holes can be plugged and re-drilled.

|

Components are easily swapped if worn.

|

Performance Requirements

Because composite materials behave differently than wood or concrete (especially regarding thermal expansion and "creep" over time), their fastening systems must pass rigorous tests:

Pull-out Strength: The force required to pull a screw out of the sleeper; composites typically achieve ≥60kN.

Torque Resistance: The material must not "strip" when the screw is tightened to the required torque (often 150-250Nm).

Lateral Resistance: The ability to withstand the "push" of a train entering a curve, measured in kilonewtons (kN).

Fastening systems for synthetic sleepers represent a "best of both worlds" solution. They allow railway engineers to use the familiar installation techniques of timber (drilling and screwing) while benefiting from the superior clamping force and fatigue life usually reserved for concrete systems.