What Are Rail Clips?

Rail clips are fastening devices used to attach rails to sleepers, preventing unwanted lateral and longitudinal movement under train loads. By keeping rails firmly in place, rail clips maintain track alignment, reduce stress on sleepers, and enhance passenger comfort.

High-quality rail clips are typically made from spring steel, composite materials, or other corrosion-resistant alloys to withstand harsh environmental conditions and heavy dynamic loads.

Key Benefits of Rail Clips

Enhanced Track Stability

Properly installed rail clips prevent rails from shifting or spreading under heavy train loads, maintaining precise track geometry.

Vibration and Noise Reduction

Elastic rail clips absorb vibrations from train movement, reducing noise in urban environments and improving ride comfort.

Durability and Reliability

Made from high-strength materials, rail clips resist fatigue, corrosion, and environmental wear, providing years of maintenance-free performance.

Ease of Installation and Maintenance

Designed for quick installation and removal, rail clips minimize track downtime during maintenance or replacement.

Compatibility with Various Sleepers

Modern rail clips work with concrete, wooden, and composite sleepers, offering flexibility for different railway designs.

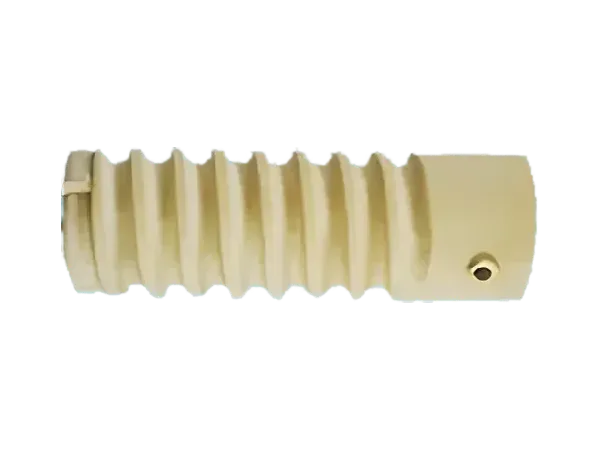

Types of Rail Clips

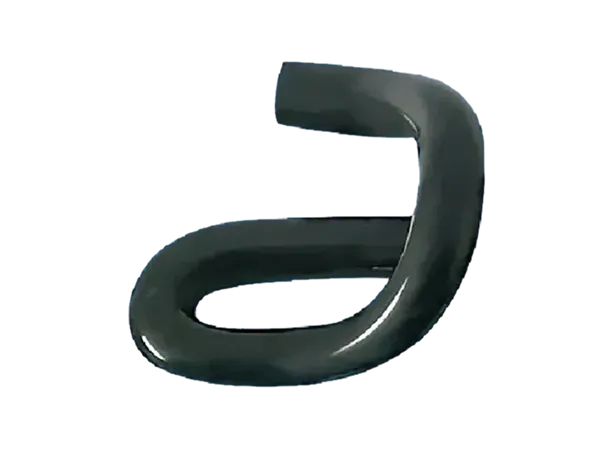

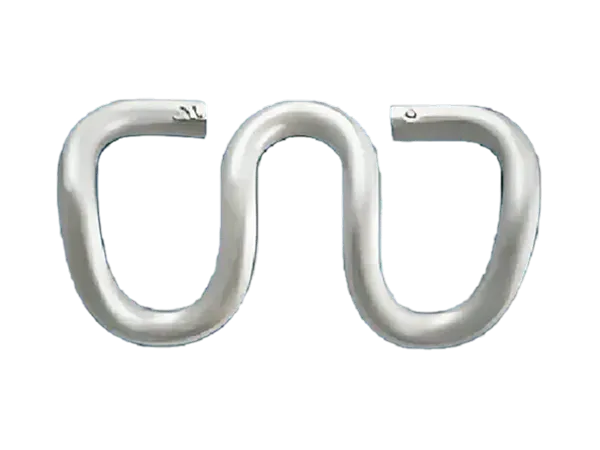

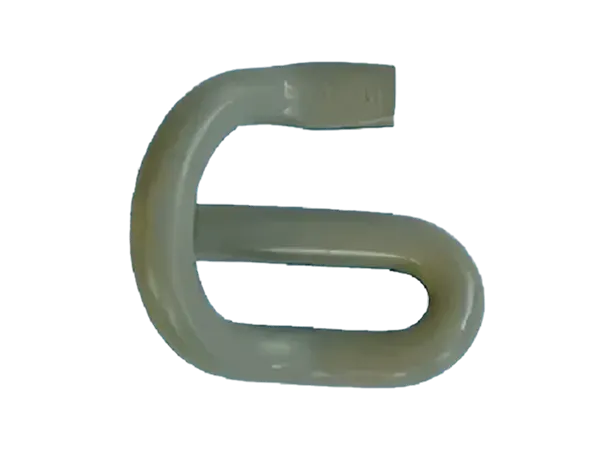

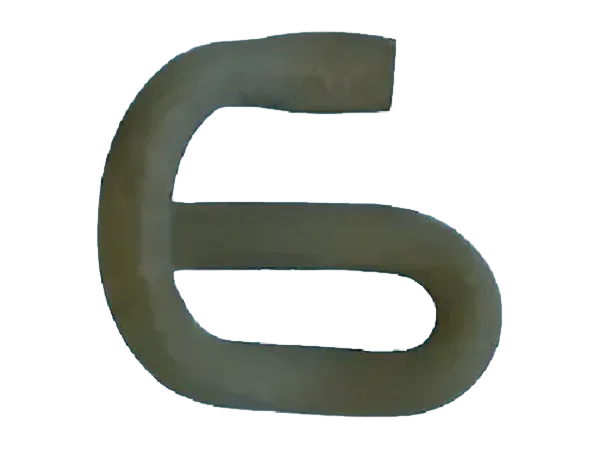

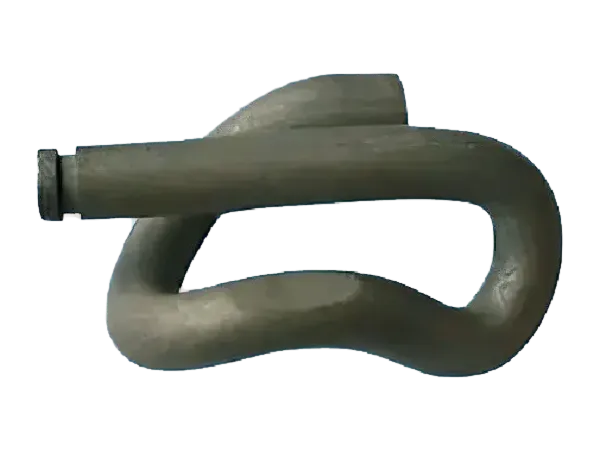

1. Elastic Rail Clips

Provide resilient fastening for high-speed railways and heavy-haul lines.

Excellent vibration-damping properties.

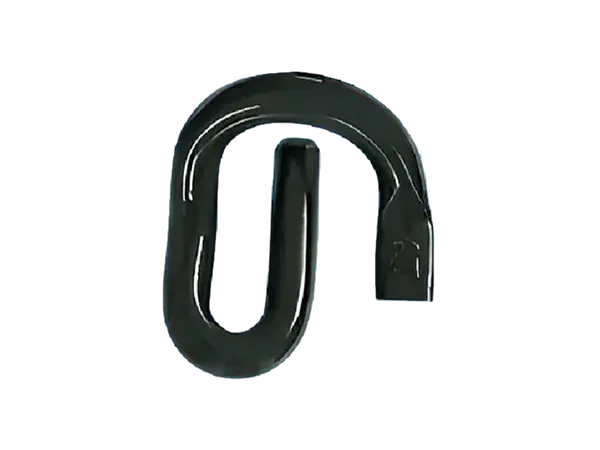

2. Pandrol Fast Clips

Widely used in modern rail networks for reliability and ease of maintenance.

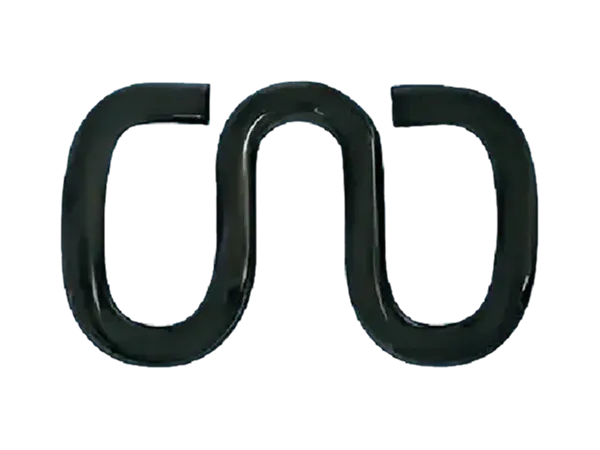

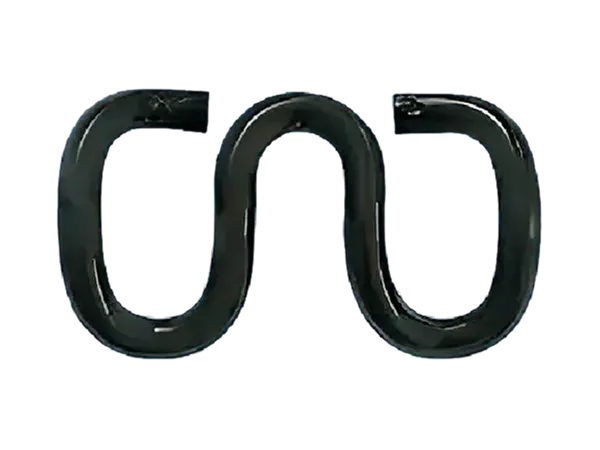

3. E-Clip and SKL-Style Clips

Common in standard gauge and regional rail systems.

Suitable for general-purpose applications.

Applications of Rail Clips

Rail clips are used across diverse railway systems:

High-Speed Railways: Maintain precise track alignment under high-speed operations.

Freight and Heavy-Haul Lines: Withstand heavy dynamic loads while ensuring safety.

Metro and Urban Transit Systems: Reduce vibration and noise in densely populated areas.

Light Rail and Regional Networks: Reliable and easy-to-install for smaller-scale operations.

How to Choose the Right Rail Clips

When selecting rail clips for your railway system, consider:

Load Capacity: Ensure the clip can withstand the train weight and frequency.

Rail Type Compatibility: Match clips to rail profile (UIC, AREMA, etc.).

Sleeper Material: Concrete, wooden, or composite sleepers require different clip designs.

Environmental Conditions: Corrosion-resistant clips are needed for humid or coastal regions.

Maintenance Requirements: Choose clips that allow easy replacement and minimal track downtime.

Installation and Maintenance Guide

Installation Tips:

Clean the sleeper and rail base before installation.

Ensure proper alignment of the clip with rail foot and sleeper seat.

Use recommended torque for fastening bolts or fastening tools.

Maintenance Recommendations:

Inspect clips regularly for signs of wear or fatigue.

Replace damaged or corroded clips promptly to avoid track instability.

Monitor track vibration and noise levels to ensure optimal performance.

FAQ – Rail Clips for Railway Track Systems

Q1: How long do rail clips typically last?

A1: High-quality rail clips can last 15–25 years depending on train frequency, load, and environmental conditions.

Q2: Can rail clips be used for both freight and passenger lines?

A2: Yes, elastic and Pandrol-type clips are versatile and suitable for heavy-haul freight, high-speed passenger, and metro lines.

Q3: Are there eco-friendly options?

A3: Yes, composite and recycled material rail clips are available, reducing environmental impact while maintaining durability.

Q4: Do rail clips reduce maintenance costs?

A4: Absolutely. Properly installed clips reduce rail and sleeper wear, lower vibration-related damage, and minimize track maintenance frequency.

Rail clips are more than just fasteners; they are essential safety and performance components for all types of railway systems. Choosing the right rail clip ensures track stability, vibration reduction, noise control, and longer service life, making your railway operations safer, more efficient, and cost-effective.

Invest in high-quality rail clips today to enhance the reliability of your railway infrastructure and reduce long-term maintenance costs.