Overview of Railway Track Bolts

Railway track bolts are essential components for securing rails, sleepers, and fastening systems in modern railway infrastructure. They ensure track stability, transmit wheel loads safely, and maintain track gauge under heavy loads and high-speed operations.

High-quality bolts are fatigue-resistant, corrosion-resistant, and compatible with vibration-damping systems, polyurethane under sleeper pads (USP), and ballast isolation mats, ensuring long-term track performance and reduced maintenance costs.

Types of Railway Track Bolts

2.1 Fish Joint Bolts

Connect rail ends using fishplates.

Designed for high tensile and shear strength.

Prevent rotation with special head design.

Common sizes: M24, M27.

2.2 Sleeper / Fastening Bolts

Secure rails to concrete, composite, or timber sleepers.

Compatible with modern vibration-damping fastening systems.

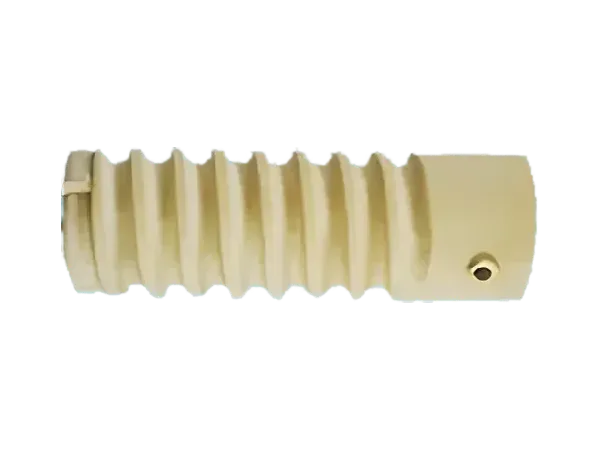

Forms: T-bolts, hex bolts, double-ended bolts.

2.3 Anchor / Foundation Bolts

Used in slab tracks, turnouts, or rail foundations.

High preloading and pull-out resistance.

Forms: L-shaped, J-shaped, chemical anchor, expansion bolts.

2.4 High-Strength Structural Bolts

Connect rails to bridges, heavy-duty tracks, and steel structures.

Common grades: 8.8, 10.9, 12.9.

Standards: ISO, EN, ASTM.

3. Materials and Surface Treatment

Materials: Carbon steel (35#, 45#), Alloy steel (40Cr, 42CrMo), Stainless steel (special environments).

Surface treatment: Hot-dip galvanizing, Dacromet, phosphating, blackening, anti-corrosion coatings.

Purpose: Enhance durability, corrosion resistance, and reduce maintenance.

4. Installation and Maintenance

Install with correct torque or tension using a torque wrench.

Use anti-loosening devices or thread-locking agents.

Initial post-installation: perform secondary tightening.

Regular inspection: check for corrosion, deformation, or loosened bolts.

Ensure proper preloading to maintain elasticity and vibration control.

5. Applications

High-speed rail, metro, and light rail systems.

Heavy-duty freight railways and industrial tracks.

Turnouts, crossings, slab tracks, and special-purpose industrial lines.

Modern vibration-damping fastening systems and USP installations.

6. FAQ / Buyer’s Guide

Q1: What types of railway track bolts are available?

A1: Fish joint bolts, sleeper/fastening bolts, anchor/foundation bolts, and high-strength structural bolts.

Q2: How to choose the right railway track bolt?

A2: Consider railway type, fastening system, sleeper material, corrosion requirements, and bolt strength grade.

Q3: Installation tips?

A3: Correct torque, anti-loosening measures, secondary tightening after initial operation, regular inspection.

Q4: How do bolts work with vibration-damping systems?

A4: Ensure preloading does not over-compress elastic elements like USP, maintaining track stability and noise reduction.

Q5: Common materials and anti-corrosion options?

A5: Carbon steel, alloy steel, stainless steel; coatings include galvanizing, Dacromet, phosphating, or special anti-corrosion layers.

Purchasing Tips:

Select according to project specifications.

Use certified materials for long-term reliability.

Match with vibration-damping fastening systems and sleeper types for optimal performance.

7. Conclusion

Railway track bolts, though small, are critical for track safety and stability. High-quality bolts, combined with modern vibration-damping systems, USP, and ballast mats, improve ride comfort, reduce noise, extend track life, and minimize maintenance costs.

Investing in proper bolts ensures that modern rail systems operate safely, efficiently, and quietly under high-speed and heavy-load conditions.