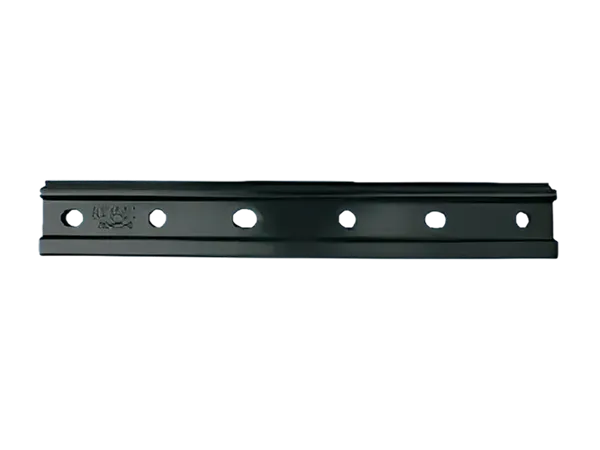

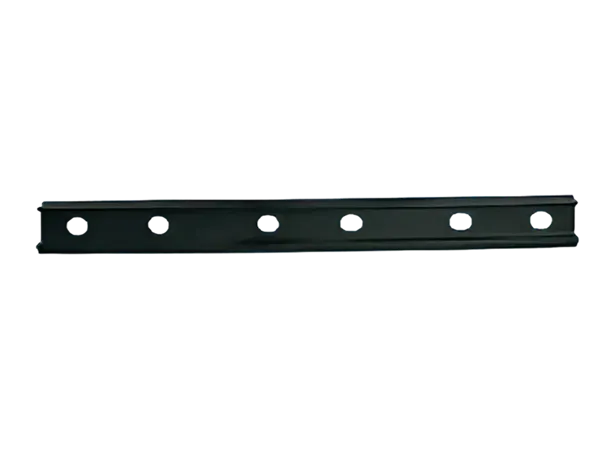

Introduction to Fishplates (Rail Connectors)

Definition: A fishplate, also known as a rail connector, is a metal plate used in railway track systems to connect two adjacent rail sections. It is typically fixed to the fishtail (end) of the rail, and the rails are tightly connected by bolts to form a continuous railway line.

Basic Characteristics:

Its shape is usually long and narrow, with a width similar to the width of the rail base plate, moderate thickness, and rectangular or slightly curved ends.

Bolt holes are drilled at both ends for fixing the rails.

The material is generally high-strength carbon steel or alloy steel to ensure load-bearing capacity and wear resistance.

Main Functions of Fishplates

Connecting Rails

It securely connects the ends of adjacent rails, forming a continuous track and ensuring smooth train operation.

Transferring Loads

Train loads are transferred to the ballast bed through the rails. The fishplate ensures even force distribution between the rails, reduces stress concentration at the ends, and prevents rail end misalignment.

Maintaining Track Geometry

Maintaining consistent track gauge, preventing excessive track clearance or misalignment, and ensuring smooth and safe train operation.

Easy Installation and Maintenance

Fishplates allow for quick assembly and disassembly during rail replacement, maintenance, or track extension, simplifying the construction process.

Material and Performance Requirements for Fishplates

Common Materials:

Carbon structural steel (e.g., Q235, Q345

Alloy steel (for high-strength or heavy-load rails)

Performance requirements:

High strength, fatigue resistance: able to withstand repeated train loads

Corrosion resistance: oxidation resistant, rust prevention

Wear resistance: reduces wear on bolt holes and ends

High precision: ensures smooth rail joints

Structural Types of Fishplates

Depending on their application and design, fishplates can be classified into the following types:

Ordinary Fishplate

Used for general railway lines

Both ends are fixed to rails, with bolt holes arranged symmetrically.

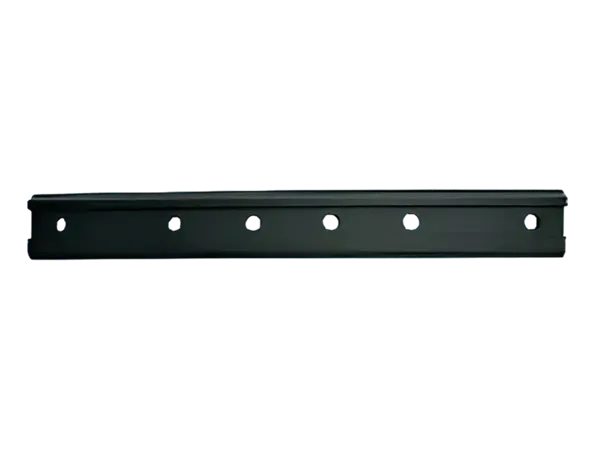

Heavy-duty Fishplate

Used for heavy-load rails or high-speed railways

Increased plate thickness, more bolt holes, stronger load-bearing capacity

Insulated Fishplate

Used for electrified railways and track circuits

The plate has an insulating layer in the middle to prevent short circuits of track current.

Adjustable Fishplate

Used for track adjustment or temperature stress compensation

Can finely adjust rail gaps or height.

Installation Method of Fishplates

Align the rail ends

Ensure the rail ends are straight, clean, and without obvious gaps.

Place the Fishplate

Snap the fishplate into both ends of the rail, ensuring the holes are aligned.

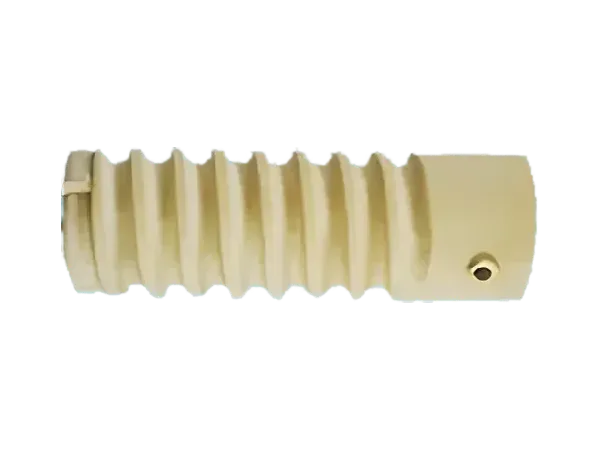

Secure the Bolts

Use high-strength bolts and tighten them, typically using a cross-tightening method to ensure even stress distribution.

Check Track Flatness

Confirm that the rail ends are aligned and the gauge is consistent; make minor adjustments if necessary.

Precautions for Use

Regularly check for loose bolts: Loose bolts may cause the rail gap to widen, affecting train stability.

Corrosion Protection: Especially in humid or coastal areas, the fishplate should be oiled or galvanized.

Avoid Fatigue Damage: Prolonged heavy-load operation may cause the fishplate to crack; it should be replaced promptly.

Temperature Stress Considerations: In high-temperature or extremely cold environments, the thermal expansion and contraction of the rail may require the use of expansion joints or adjustable fishplates.

Summary

Although a small component in the railway track system, the fishplate plays a crucial role in rail connection, load transfer, and track stability. Proper material selection, correct installation, and regular maintenance are key to ensuring safe railway operation and extending track life.