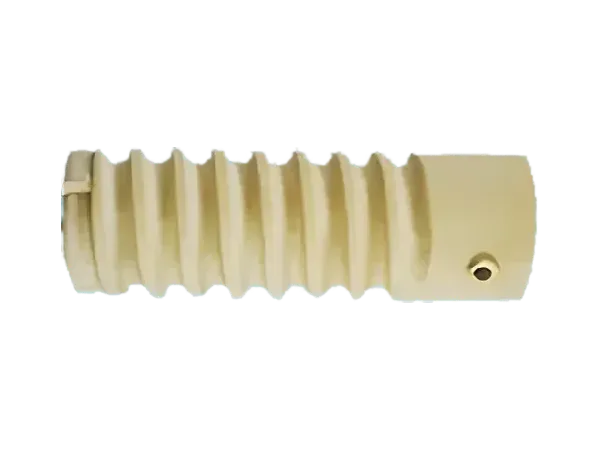

Overview of Plastic Dowels

Plastic dowels are auxiliary components used in railway track systems for track fastening, typically installed between track fasteners, bolts or nuts, and sleepers. Their main functions are:

Protecting fasteners from wear

Improving the uniformity of fastening force

Reducing vibration and noise

Preventing direct contact between moisture, dust, and corrosive substances and metal fasteners

They are usually small in size but play a crucial role in the long-term stability of the track system.

Functions of Plastic Dowels

Shock Absorption and Cushioning

During train operation, the track is subjected to enormous impact forces. Sleeves provide a degree of elasticity, reducing direct friction between sleepers, rails, and fasteners, thereby reducing noise and vibration.

Protecting Metal Fasteners

Sleeves isolate bolts, nuts, and sleepers, reducing direct contact between metal and wood or concrete, preventing bolt loosening or corrosion.

Distributing Pressure

When fasteners are under stress, sleeves can evenly distribute pressure, reducing localized stress concentration, thus extending the service life of sleepers and track fasteners.

Waterproof and Dustproof

High-quality plastic dowels typically possess excellent corrosion resistance, preventing moisture and dust from penetrating the threaded areas and reducing the risk of rust.

Materials of Plastic Dowels

Railway plastic dowels are generally made of high-performance engineering plastics. Common materials include:

Polyethylene (PE): Good wear resistance and corrosion resistance, but generally poor high-temperature resistance.

Polypropylene (PP): High mechanical strength, good chemical corrosion resistance, and economical price.

Polyamide (PA/Nylon): High strength, wear resistance, and aging resistance, suitable for high-load tracks.

Glass Fiber Reinforced Plastic (FRP/PA+GF): Used in heavy-haul and high-speed railways, capable of withstanding greater shear forces and pressure.

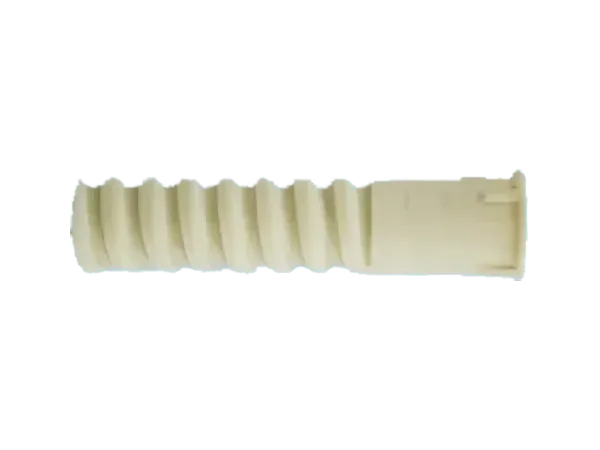

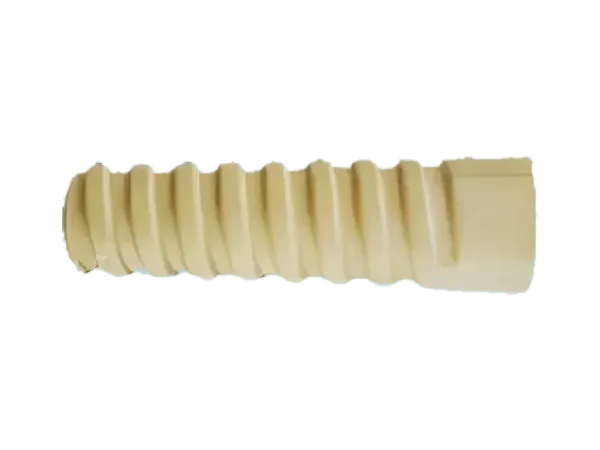

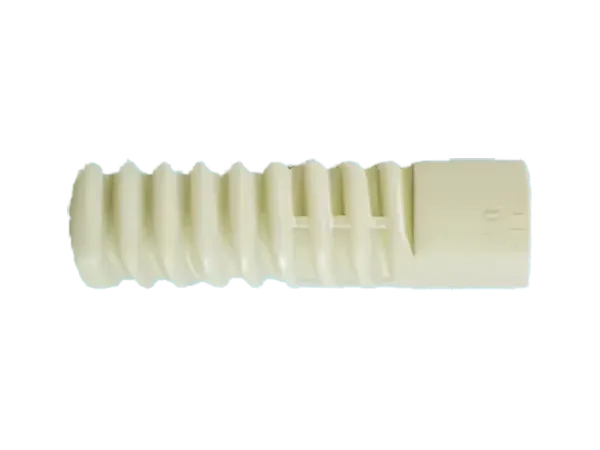

Types of Plastic Sleeves

Depending on the track system and fastener type, plastic sleeves can generally be classified as:

Bolt Dowels

Installed in sleeper holes to isolate bolts and sleepers, protecting the bolts and reducing friction.

Nut Bushing/Washer Dowels

Used with nuts to distribute pressure evenly and prevent loosening.

Sleeper Bushing

Installed in pre-drilled holes in sleepers to reduce bolt hole wear; suitable for concrete and composite sleepers.

Vibration-Damping Dowels

Made of elastic plastic or composite materials, effectively absorbs vibrations generated by train operation.

Application Scenarios

Ordinary Railways: Reduces wear on traditional wooden or concrete sleepers and protects fasteners.

High-Speed Railways: Ensures long-term stability of track system fasteners in high-frequency vibration environments.

Heavy-Haul Railways: Withstands high shear forces and pressures, extending track service life.

Special Track Systems: Such as industrial railways, port tracks, and mining tracks; chemically resistant or wear-resistant materials can be selected depending on the environment.

Installation and Maintenance

Installation

The dowels should be intact and free of cracks before being placed in the pre-drilled hole in the sleeper.

After the bolts pass through the sleeve, install the washers and nuts to ensure even tightening force of the fasteners.

Avoid sleeve misalignment or damage, as this may lead to uneven stress distribution.

Maintenance

Regularly inspect the sleeves for aging, cracks, or wear.

Damaged sleeves should be replaced promptly to prevent loosening or track damage.

For high-load or high-speed railways, sleeves made of wear-resistant and aging-resistant materials should be selected to extend their service life.

Summary

Although small in size, plastic sleeves in railway track systems play a crucial role, mainly in:

Providing shock absorption and cushioning

Protecting fasteners and sleepers

Distributing stress and reducing wear

Providing waterproofing and dustproofing, extending track service life

By rationally selecting materials, types, and installation methods, plastic dowels can significantly improve the safety, durability, and stability of track systems.