Dedicated Fastening System for Port Gantry Cranes Introduction

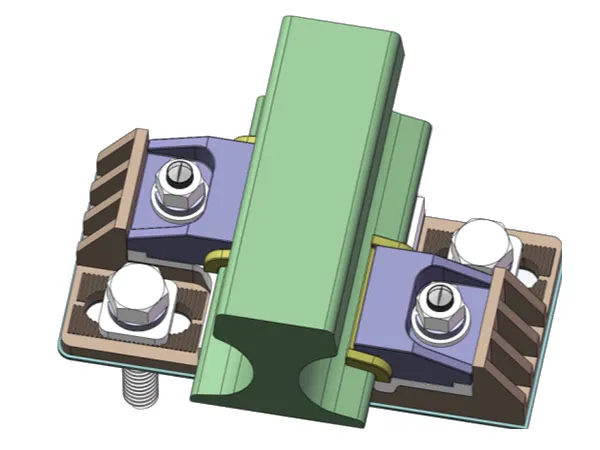

Thespecial rail press fastening system is a dedicated fastening system developed for crane, gantry crane, and runway rail systems used for fully automated container handling at ports, railway freight yards, etc. It is suitable for systems in automated terminals or railway freight yards, meeting the requirements of heavy-duty equipment like container cranes. It can maintain a reliable connection between the rail and the track structure effectively over the long term, possessing sufficient longitudinal resistance, high track adjustment capacity, and suitable elasticity. The components have simple structures, are easy to install and disassemble, and are durable.

Our fastening systems are designed specifically for port gantry cranes, combining high-strength materials, anti-vibration technology, and corrosion resistance to withstand harsh marine environments. They are compatible with all models and sizes, offering tailor-made solutions for both new installations and retrofitting projects.

Key Features

High Load-Bearing Capacity

Engineered to secure heavy crane components, including the gantry beams, trolley rails, and support structures.

Maintains structural stability even under extreme dynamic loads during container lifting and movement.

Vibration and Shock Absorption

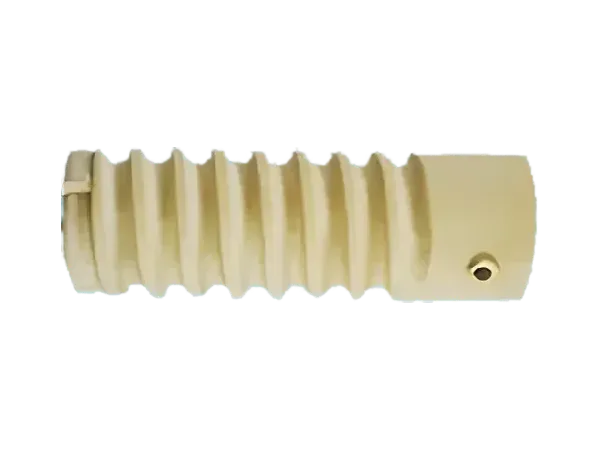

Incorporates advanced damping materials to reduce vibrations caused by crane operation.

Extends the service life of crane components and minimizes wear on rails and bearings.

Corrosion and Environmental Resistance

Made from marine-grade steel or specially coated alloys to resist salt spray, humidity, and temperature fluctuations.

Suitable for port environments with heavy exposure to water, wind, and sun.

Universal Compatibility

Supports all models of port gantry cranes, including semi-gantry and full-gantry designs.

Modular design allows easy replacement, maintenance, and upgrades without major structural modifications.

Precision Engineering

Ensures exact alignment of crane rails and structural components for smooth trolley operation.

Reduces maintenance downtime and enhances operational efficiency.

Applications

Container Terminals: Ensures stable, high-speed handling of containers with minimal downtime.

Bulk Material Ports: Supports heavy-duty cranes handling coal, ore, or grain efficiently.

Ship-to-Shore Operations: Provides secure and vibration-resistant fastening for smooth container transfer.

Main Performance Parameters

|

NO.

|

Item Name

|

Performance Indicator

|

Test Method

|

|

1

|

Static Stiffness

|

185±20kN/mm

|

EN13146-4

|

|

2

|

Anti-creep Resistance

|

≥18kN

|

EN13146-1

|

|

3

|

Pull-out Resistance of Embedded Parts

|

≥60kN

|

EN13481-2

|

|

4

|

Corrosion Resistance

|

Can be disassembled normally after 300h salt spray test

|

EN13146-6

|

|

5

|

Fatigue Performance

|

No damage to components after 5 million cycles of vertical loading 30~300kN

|

EN13146-4

|

|

6

|

Rail Height Adjustment Capacity

|

0~+50mm

|

/

|

|

7

|

Rail Gauge Adjustment Capacity

|

+45mm~-15mm

|

/

|

Advantages of Using Our Dedicated Fastening System

Extended Crane Lifespan: Reduces mechanical stress on critical crane components.

Enhanced Safety: Prevents structural failures and operational accidents.

Reduced Maintenance Costs: Minimizes rail wear, component fatigue, and vibration-related damage.

Optimized Performance: Improves crane movement precision and load handling stability.