What is a Rail Spike?

A rail spike is the most basic and traditional fastener in a railway track system. It is primarily used to securely fix rails to wooden or certain composite sleepers, ensuring rail stability and preventing lateral and longitudinal displacement. Rail spikes are typically hammered or mechanically driven into the sleeper and used in conjunction with the rail base or pad.

Although modern railways increasingly use elastic clip systems, rail spikes are still widely used on traditional lines, mining railways, industrial dedicated lines, and temporary track-laying projects.

The Role of Rail Spikes in Track Systems

In railway track structures, rail spikes primarily perform the following functions:

Fixing the rails: Reliably connecting the rails to the sleepers to maintain a stable track gauge.

Transferring loads: Transferring train loads from the rails to the sleepers.

Preventing creep: Resisting longitudinal rail movement caused by train braking forces and temperature changes.

Used in conjunction with rail pads: Sharing pressure with rail pads and bases to reduce sleeper damage.

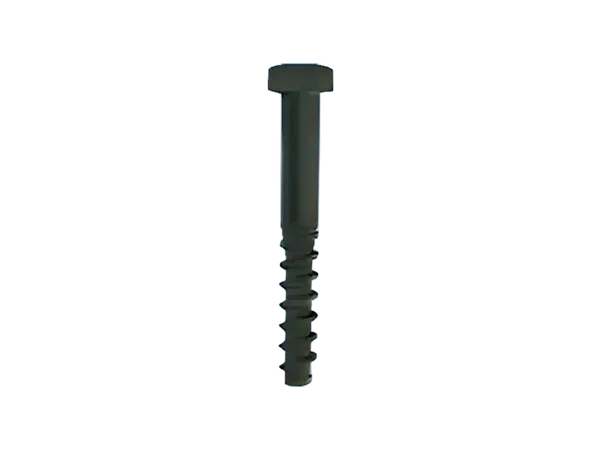

Structural and External Characteristics of Rail Spikes

Typical rail spikes are square or flat-sectioned, with a sharp end for easy driving into the sleeper; the other end is a flat head used to clamp the rail to the bottom or pad.

Main structural features include:

Head: Bears pressure and prevents sinking.

Shaft: Provides pull-out resistance, often square or barbed.

Tilt: Facilitates insertion into the sleeper.

Some rail spikes undergo anti-corrosion treatments, such as hot-dip galvanizing, black coating, or asphalt coating, to improve weather resistance.

Common Types of Rail Spikes

Based on structure and application, rail spikes can be classified as:

Square Spikes: The most common type, used for wooden sleeper tracks, economical and practical.

Cut Spikes: Cut from steel plate, with good pull-out resistance, commonly used on heavy-load lines.

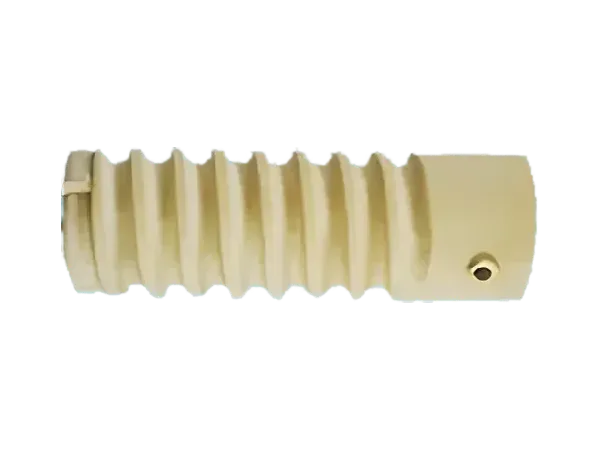

Screw Spikes: Have a threaded structure, providing even stronger pull-out resistance, suitable for high-vibration environments or rigid sleepers.

Dog Spikes: With a bent head, commonly found on light rail or industrial lines.

Common Materials for Rail Spikes

Medium Carbon Steel / High Carbon Steel: High strength, impact resistant

Alloy Steel: Used for heavy loads or high fatigue conditions

Surface Treatments: Hot-dip galvanizing, Dacromet coating, oiling for rust prevention, etc.

Conforms to common standards such as ASTM A65, AREMA, EN, TB/T, etc.

Applicable Sleepers and Application Scenarios

Applicable Sleeper Types:

Wooden sleepers (most common)

Composite sleepers / Synthetic sleepers

Some temporary concrete bases used with sleeves

Typical Applications:

Conventional railways and branch lines

Dedicated lines for mines, ports, and metallurgical enterprises

Light rail and trams

Temporary construction tracks and maintenance lines

Advantages and Limitations of Track Spikes

Advantages:

Simple structure, easy installation

Low cost, easy maintenance and replacement

Strong adaptability to wooden sleepers

Suitable for temporary and low-speed lines

Limitations:

Limited pull-out resistance, prone to loosening over time

Poor vibration damping performance

Unsuitable for high-speed and heavy-haul railways

Limited ability to control track gauge accuracy

Therefore, in high-speed railways and urban rail transit, they have been gradually replaced by flexible fastening systems.

Comparison with modern fastening systems

Item

|

Rail Spikes

|

Flexible Fastener System

|

Fixing Method

|

Rigid Fixed

|

Elastic Clamping

|

Vibration Reduction Performance

|

Low

|

High

|

Installation Efficiency

|

Mainly by Human Labor

|

High Degree of Mechanization

|

Maintenance Frequency

|

High

|

Low

|

Applicable Routes

|

Low-speed, Temporary, Dedicated Lines

|

High-Speed, Heavy-Load, Urban Rail

|

Installation and Maintenance Key Points

Ensure accurate track gauge and pad placement

Use specialized nailing tools to prevent sleeper cracking

Conduct regular inspections; promptly repair or replace any loose sleepers.

In corrosive environments, it is recommended to use anti-corrosion coated track spikes.

Development Trends

As railways develop towards higher speeds, heavier loads, and lower maintenance, the application of track spikes is gradually focusing on:

Industrial railways, mining railways

Maintenance and partial replacement of old lines

Dedicated fastening solutions for synthetic sleepers and other specific areas. Simultaneously, track spikes are also being improved towards higher strength, corrosion resistance, and spiral designs.

As one of the most traditional fasteners in railway track systems, track spikes still play an important role in specific scenarios. They are simple in structure, low in cost, and easy to install, making them particularly suitable for wooden sleeper lines and industrial railways. However, in modern high-speed lines with high vibration reduction requirements, they are gradually being replaced by more advanced elastic fastening systems.