PU Synthetic Sleepers Overview

PU Synthetic Sleepers are railway sleepers made with polyurethane (PU) foam composite material as the matrix and reinforced with glass fiber or other reinforcing materials.

They completely mimic the shape and size of wooden sleepers, but in terms of internal structure and performance, they integrate modern polymer and composite material technologies, combining high strength, lightweight, and durability.

In short, they are a "performance-upgraded alternative to wooden sleepers".

Why are More and More Railway Projects Choosing PU Synthetic Sleepers?

✅ 1. Extended Service Life

PU synthetic sleepers are resistant to aging, fatigue, and hydrolysis, with a designed lifespan typically exceeding 50 years, significantly longer than traditional wooden sleepers, reducing overall lifespan replacement and maintenance costs.

✅ 2. Excellent Environmental Resistance

Rot-resistant and insect-resistant

Waterproof, moisture-proof, and acid/alkali resistant

Suitable for complex environments such as humid, cold, and coastal areas

Ideal for use in tunnels, bridges, and special sections.

✅ 3. Lightweight and High-Strength, Easier to Install

Compared to concrete sleepers, PU synthetic sleepers are lighter, facilitating transportation and manual installation, while maintaining sufficient load-bearing capacity to meet the demands of heavy-load and high-speed lines.

✅ 4. Good Vibration Reduction and Insulation Properties

Polyurethane material itself possesses excellent elasticity and damping properties, effectively reducing track vibration and noise;

At the same time, its good electrical insulation properties contribute to the stable operation of the track signaling system.

✅ 5. Environmental Protection and Sustainability

No preservatives are used, no harmful substances are produced, and some materials are recyclable, meeting the requirements of modern railways for green infrastructure.

Typical Applications of PU Synthetic Sleepers

Thanks to their comprehensive performance, PU synthetic sleepers are widely used in applications requiring higher reliability:

High-speed and intercity railways: Excellent fatigue resistance and stability

Subways and urban rail transit: Significant advantages in vibration reduction, noise reduction, and insulation

Bridges, tunnels, and turnout sections: Customizable to adapt to complex structures

Existing line renovation and maintenance: Sizes can mimic wooden sleepers for easy replacement and upgrades

Advantages Compared to Traditional Railway Sleepers

Item

|

Wooden Sleeper

|

Concrete Sleepers

|

PU Synthetic Sleepers

|

Service life

|

10–20 years

|

30–50 years

|

50 years or more

|

weight

|

light

|

Very heavy

|

Lighter

|

Corrosion-resistant/waterproof

|

Difference

|

good

|

Excellent

|

Insulation performance

|

generally

|

Poor

|

excellent

|

Maintenance costs

|

high

|

middle

|

Low

|

Environmental protection

|

Low

|

middle

|

high

|

Overall, PU synthetic sleepers have significant advantages in terms of lifespan, maintenance, construction efficiency, and environmental friendliness.

PU Synthetic Sleepers FAQ

1. What materials are PU Synthetic Sleepers made of?

PU synthetic sleepers use polyurethane (PU) foam composite material as the matrix, and typically incorporate glass fiber or other reinforcing fibers to improve strength and stiffness. They are a high-performance composite synthetic sleeper.

2. Can PU synthetic sleepers completely replace wooden sleepers?

Yes. PU synthetic sleepers can maintain the same size, shape, and installation methods as wooden sleepers, but they are superior to wooden sleepers in terms of lifespan, corrosion resistance, strength, and environmental friendliness, making them an ideal upgrade alternative.

3. How long is its service life?

Under normal operating conditions, PU synthetic sleepers are typically designed for a lifespan of over 50 years, far exceeding the 10–20 years of traditional wooden sleepers, significantly reducing long-term replacement and maintenance costs.

4. Is it suitable for humid or coastal environments?

Excellent. PU material is non-absorbent, non-rotting, and resistant to salt spray and chemical corrosion, maintaining stable performance in tunnels, bridges, coastal areas, and high-humidity regions.

5. Does the sleeper have good electrical insulation properties?

Yes. PU synthetic sleepers have excellent electrical insulation properties, making them particularly suitable for railways and urban rail transit lines with high requirements for signaling systems.

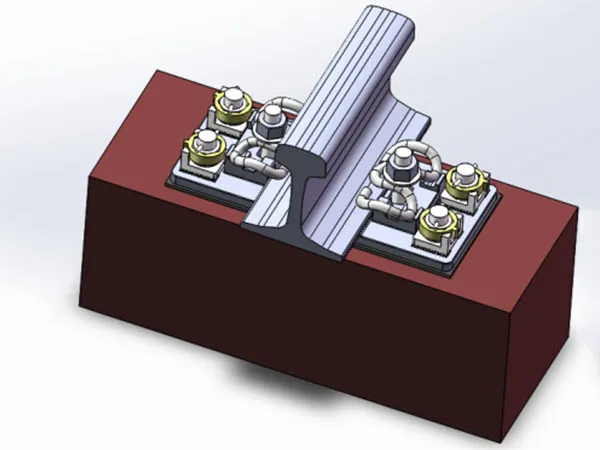

6. Does it support customized sizes and drilling?

Yes. PU synthetic sleepers can be customized in length, cross-section, embedded parts, and drilling locations according to project requirements, making them ideal for special conditions such as turnouts and bridges.

7. What are the advantages compared to concrete sleepers?

Compared to concrete sleepers, PU synthetic sleepers:

Lighter, easier to install

Better vibration reduction and noise reduction performance

Easier to cut and reprocess

More friendly to bridge structural loads

8. Are PU synthetic sleepers environmentally friendly?

Yes. It does not contain the toxic chemicals commonly found in preservative-treated wood, making its production and use more environmentally friendly. Some materials are recyclable, aligning with sustainable development trends.

9. Is the installation method complicated?

No. The installation method is similar to that of wooden sleepers, compatible with common fastening systems, requiring no major modifications to existing construction techniques.

10. Which track types is it suitable for?

Suitable for:

High-speed railways

Heavy-haul railways

Urban rail transit

Bridges, tunnels, and turnout sections

Old line renovation projects